Search

Search

Search

Search

Create smaller mining footprints, reduce operational costs, and improve operational efficiency with Halliburton DLE technology and services.

Contact UsAs global electrification accelerates, the demand for critical minerals like lithium continues to rise. Lithium-ion batteries—essential to electric vehicles and renewable energy storage—are at the heart of this transformation. To support these growing energy needs, Halliburton helps design and deliver efficient, sustainable direct lithium extraction (DLE) solutions.

Meeting the demand for responsibly and locally sourced lithium requires faster, more efficient production methods. Traditional mining is time-intensive and consumes significant land and water resources. In contrast, DLE technologies offer a quicker path to production with a smaller environmental footprint.

DLE extracts lithium from brine more rapidly and with less environmental impact than conventional evaporation ponds. With advanced technologies, we can help customers maximize lithium yield from the same volume of brine while minimizing impact.

DLE CASE STUDY

A customer launched an appraisal project in the Smackover Formation in Arkansas to enter the DLE market and become a leading lithium producer. Halliburton helped reduce standard appraisal well drilling days by 5.2 days (-24.8%).

Halliburton draws upon its decades of subsurface evaluation, fluid sampling and analysis, drilling, artificial lift systems, well construction, and completion solutions experience to help customers expand into DLE. Our methods, technologies, and best practices enable smaller project footprints that have less environmental impact, lower costs, and better efficiency.

Our geologists and industry-leading software provide detailed subsurface models. This helps operators identify lithium-rich formations with the most potential. We deliver in-depth geological insights that help reduce risk and accelerate exploration through customer data integration.

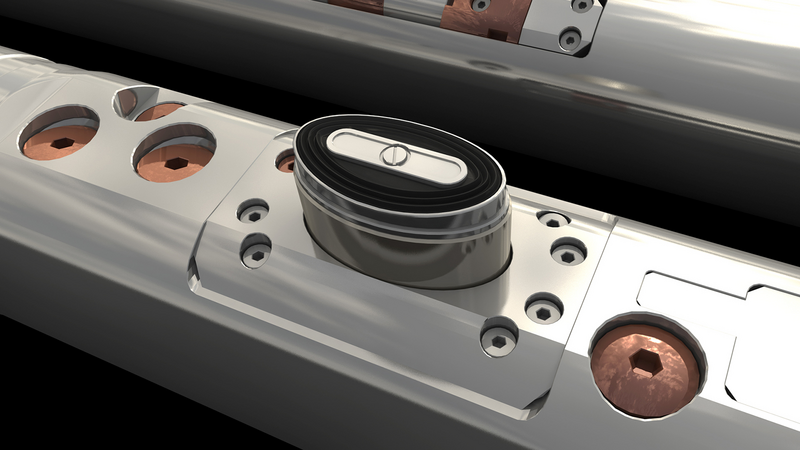

Operators require high-quality, low-contamination fluid samples to understand brine chemistry and optimize extraction. Halliburton wireline technologies, honed in the oilfield, gather formation pressure, identify fluids, and test samples in a single pass. This maximizes efficiency and data quality.

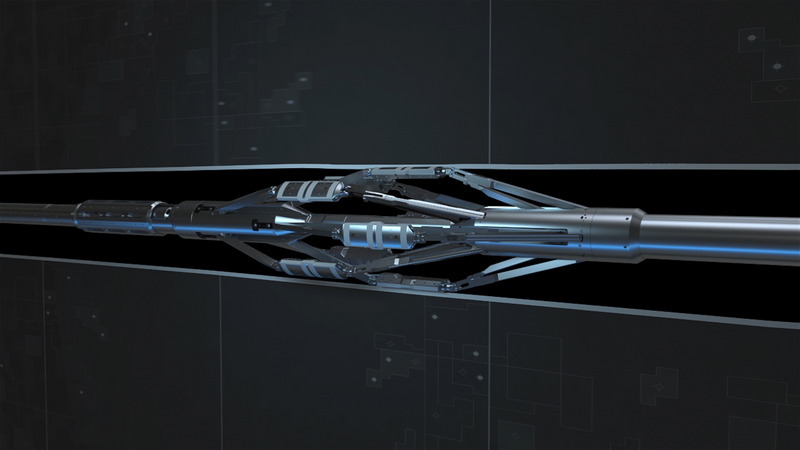

Efficient dewatering maximizes lithium recovery from brine. We engineered our MineESP™ electric submersible pumps and horizontal pumping systems for harsh mining environments. They provide reliable, agile dewatering with remote monitoring capabilities.

Optimized drilling fluids help ensure safe, efficient operations. Our portfolio includes fluids designed for performance in brine, saltwater, or freshwater environments. This offers stability at high temperatures and excellent suspension without clays.

High temperatures and thermal expansion in geothermal and DLE wells can damage the cement, casing, and equipment. This results in a loss of zonal isolation, gas migration, and eventually abandonment. Halliburton helps reduce risk for the life of the well by providing engineered solutions that increase wellbore integrity and lower the risk of well abandonment.

With Summit ESP® expertise and top tier technology, MineESP™ pumping systems address the toughest problems in controlling groundwater inflows.

Combines innovative technology and tightly integrated, end-to-end suite of cross-domain workflows to increase subsurface understanding, reduce uncertainty around today’s most complex reservoirs and tackle future energy challenges.

StrataXaminer™ provides more accurate well data to better evaluate production potential and increase return on investment.

Predictive modeling to validate and optimize well design.

ThermaLock™ cement is a non-Portland, low permeability barrier system that is nonreactive with CO₂ and is ideal for ultrahigh-temperature applications.

Fluid identification and sampling solution.

Direct formation pressure measurements on-demand.

Reservoir Xaminer™ grants high-quality formation evaluation data in real-time for improved data quality, optimized rig time, and a higher asset value.

Simple, plug-and-play surface solution that feeds into our geothermal downhole pump when conducting well inflow performance tests.