Search

Search

Search

Search

Our integrated, engineered wellbore cleanout solution effectively cleans your well, preparing it for completion and achieving customer-specified requirements while minimizing rig time and waste fluids.

Halliburton CleanWell Solutions addresses the entire operation. We gather and analyze well and installation data to help create a custom solution comprising spacers and pills, along with a surface filtration system. Our mechanical cleanup tool configuration is selected based on each well’s unique design. In conjunction with the customized pill and spacer design, this configuration provides operators with a tailored solution to maximize debris recovery.

By incorporating our proven and systematic processes, we deliver an optimum solution to maximize the efficiency of your cleanup operation – along with your completion – to help you reduce operating costs and minimize nonproductive time.

By collaborating with customers every step of the way, we are able to continuously refine our software modeling systems to identify risks and mitigate potential unscheduled events. Being one step ahead means quick response times on the rig, along with increased production and reduced costs.

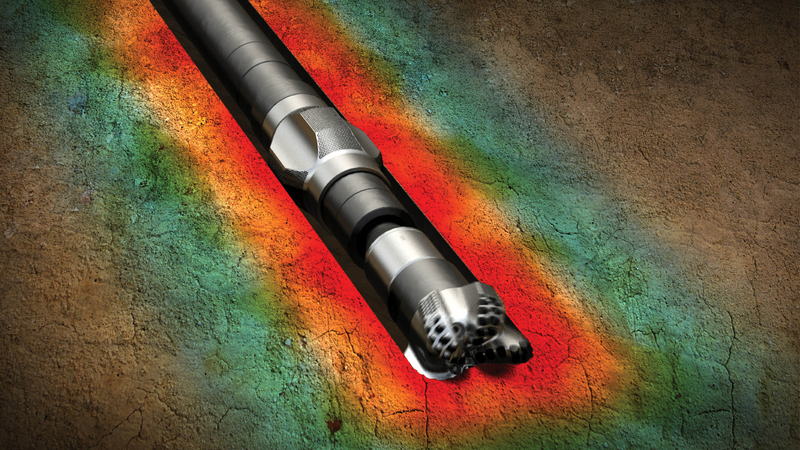

Not only do CleanWell® tools allow for a single trip, but our latest generation also boasts the largest inner diameter, resulting in optimized hydraulics and debris removal. When coupled with our customized chemistry, the result is an industry-leading cleanout solution. At surface, Halliburton provides custom-built filtration units capable of achieving twice the flow rate of standard systems.

If an issue is ever identified, our problem resolution process helps ensure that the root cause is identified and presented to the customer as soon as possible. Together, we will plan and respond until a solution has been identified and implemented.

A proven combination of wellbore cleaning tools, chemicals, and filtration services was required so that the operator would not experience additional operational costs and completion delays. Challenges included:

Did you know that up to 30% of the non-productive time (NPT) during the well completion phase is directly related to debris left in the wellbore after drilling? Wellbore debris presents a major risk to the well and completion operations, making it imperative to have a robust solution for wellbore cleanup before completing the well. Debris can be a major contributor to incidents, including:

Halliburton CleanWell® Solutions comprises the latest generation of filtration services, wellbore cleanup fluids, mechanical wellbore cleaning tools, and optimized software modeling to protect production, prolong the life of the well, and help maximize productivity.

Complete portfolio of filtration services, wellbore cleanup fluids, mechanical wellbore cleaning tools, and software modeling.

Advanced wellbore cleaning with BaraKlean® well cleaners.