Search

Search

Search

Search

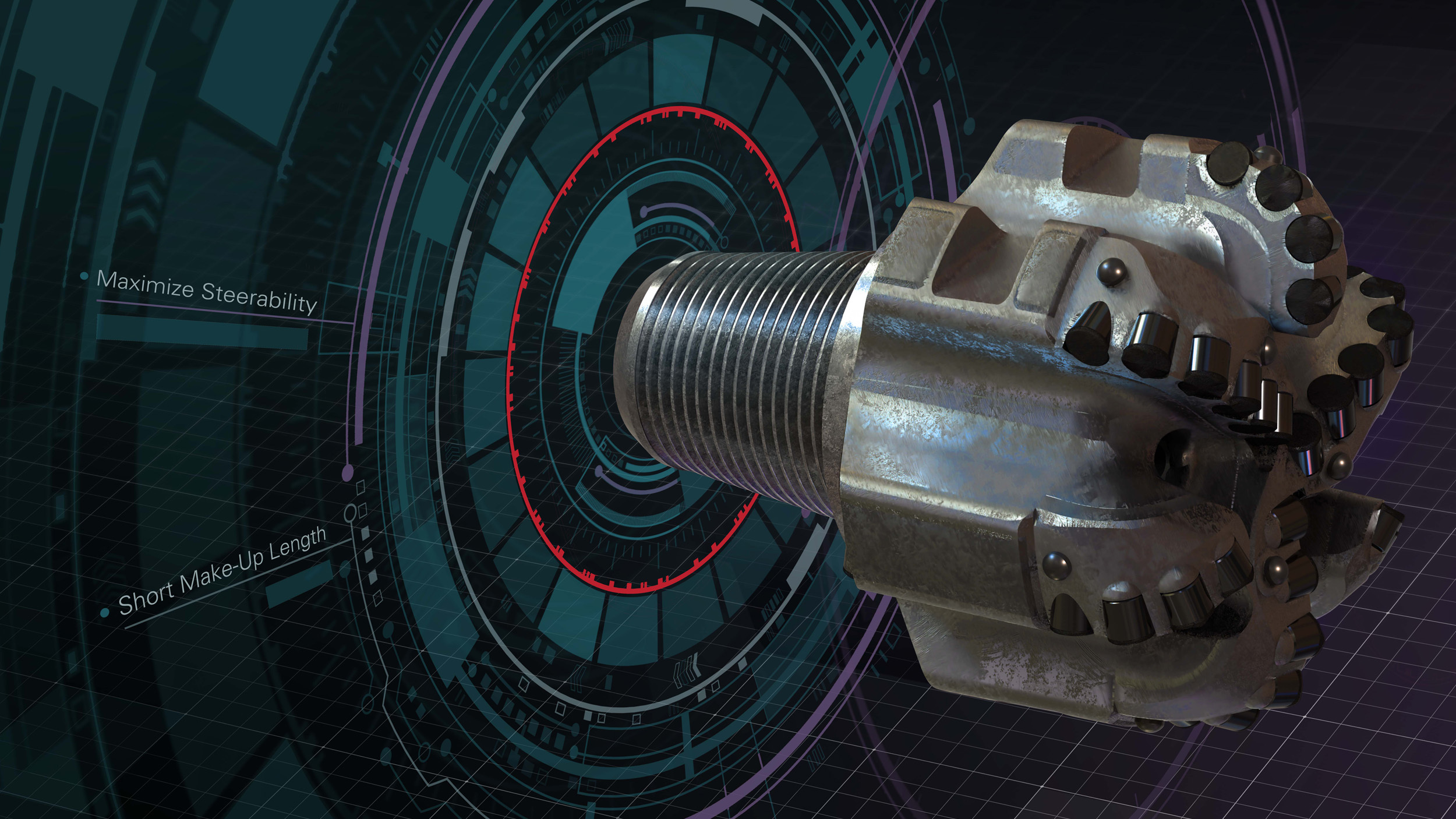

Designed for high build rates in curve and lateral applications

TALK TO AN EXPERTDrilling a curve and lateral using a rotary steerable system (RSS) tool necessitates a highly steerable bit to meet dogleg severity requirements. Simultaneously, the bit must remain stable during higher rates of penetration (ROP) to minimize harmful shocks and vibrations while drilling the lateral. HyperSteer drill bits address both challenges by reducing makeup length and maintaining sufficient gauge length. The reduced makeup length allows the RSS to transfer more force to the drill bit, enhancing side cutting and achieving higher build rates. Meanwhile, the gauge length ensures stability in the lateral, particularly when ROP is increased.

world oil / october 2023

Drilling challenges remain the same: drill faster and more efficiently. Read about how the HyperSteer™ directional drill bit and iCruise® X rotary steerable system are consistently drilling the vertical, curve, and lateral in one run.

read articleLearn how the operator drilled their first-ever four-mile lateral in a single run, reaching a total depth (TD) of 30,315 ft

1:12

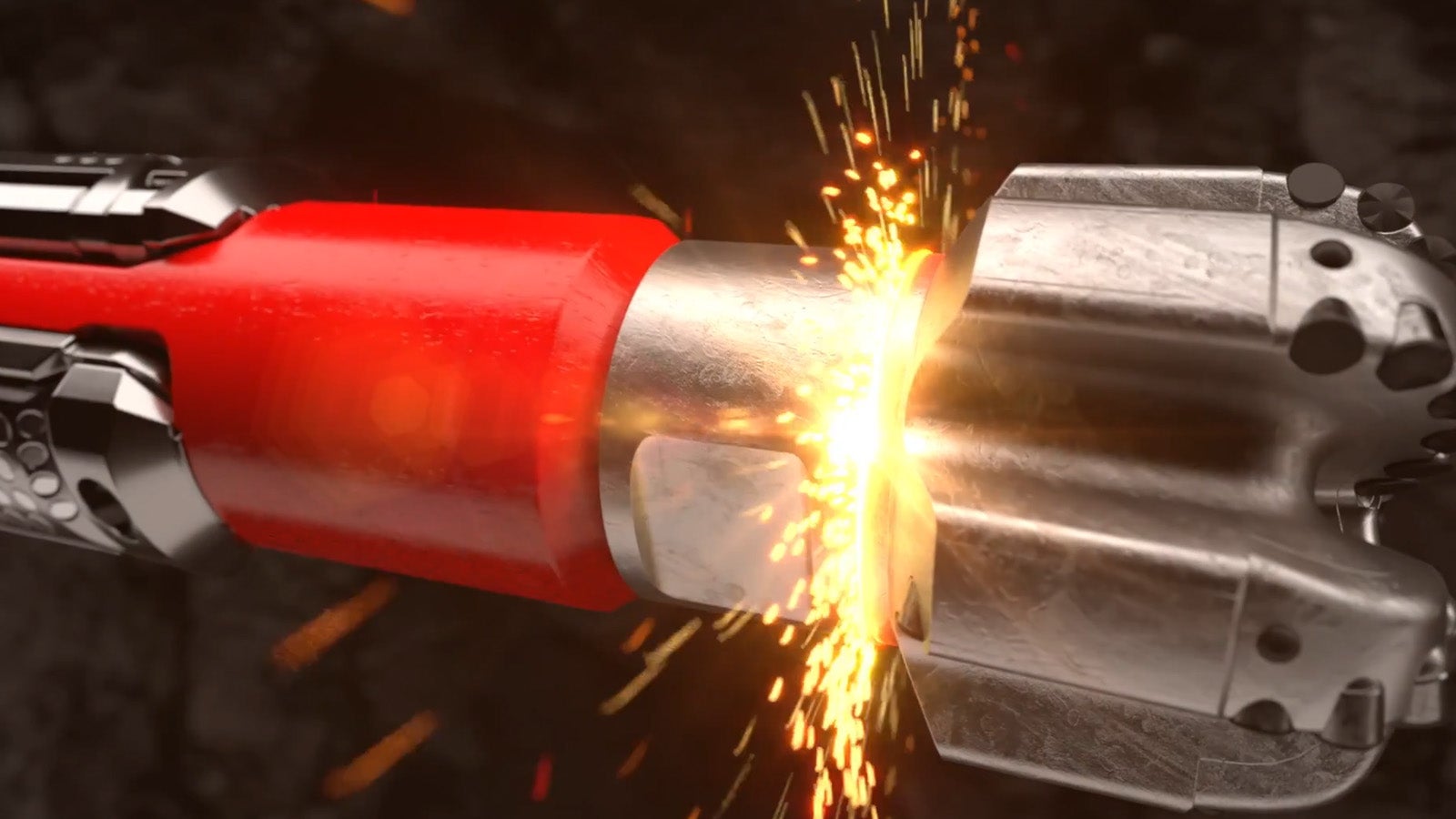

HyperSteer directional drill bits are designed to minimize makeup length without eliminating the gauge pads. Historically, one of the primary means of reducing makeup length was by shortening, and in some cases, eliminating the gauge pads. However, while shortening the gauge length may increase build rate capabilities, it trades off stability and ultimately, durability. HyperSteer drill bits solve these issues by moving the breaker slot into the gauge pad and reducing length through elimination of the shank.

Reduced makeup length for high build rates in curve and lateral applications

0:34

The Hedron® platform of fixed cutter drill bits combines state-of-the-art technology with an industry-leading customization process.

Explore

Juggernaut® cutter technology for increased impact and abrasion resistance.

Explore

Geometrix™ 4D-shaped cutters use different geometries to optimize drilling efficiency and durability.

Explore