Search

Search

Search

Search

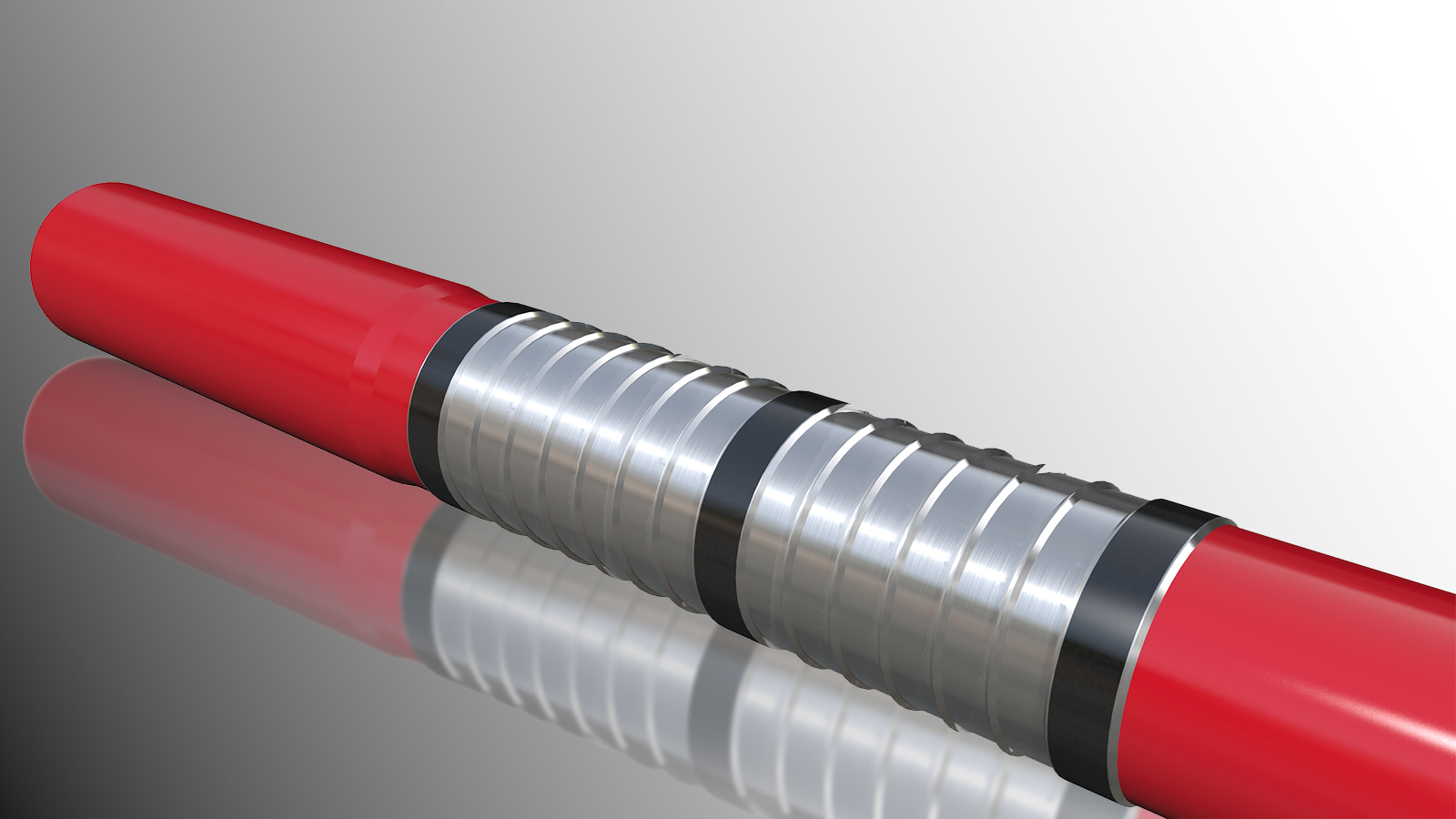

VersaFlex® and XtremeGrip® expandable liner hanger systems deliver reliability to resolve challenges from total fluid loss to complex deepwater installations

Download PDFDeep Water

Provide reliable liner hanger solutions for total fluid loss

Colombia

Provide reliable liner hanger solutions under the following conditions:

More than 1,000 successful ELH installations performed in Colombia with excellent HSE and service quality

For almost 20 years, expandable liner hanger (ELH) technology solutions have been used by various oil and gas operators both on and offshore. Well construction in these complex and varied environments involves challenges, such as total fluid loss, highly reactive zones that form tight spots in short time periods, high-rate cement operations with string rotation, and remote locations (i.e., deepwater wells) that require robust, adaptive, and reliable tools to address specific needs with excellent service quality.

Traditionally, conventional liner hangers were not the preferred solution in such environments. Installations were performed only in certain fields, primarily in reactive intermediate well sections or shallow well completions with screens or slotted liner. However, as challenging conditions increased over time attributed to reservoir depletion and the higher wash and ream capabilities necessary to overcome problematic zones in unstable shale, conventional tool capabilities and reliability were compromised. Thus, solutions, such as ELH technology, were developed.

The first successful ELH installation was performed in the southern region of Colombia in August 2005 using 7 × 9 5/8-in. equipment. The southern Colombian basin (known as the upper Amazon basin) is shared with Ecuador and Peru. This formation contains some intercalated shale and limestone, which makes reaching target depth difficult while casing the hole because of the changes in hole diameter. The rotational capabilities necessary to wash and ream during deployment were met by the ELH technology. The successful completion of these wells using ELHs established entrance to the market segment.

ELH technology was established within the Colombian market with an unmatched 94% job efficiency rating after 100 operations performed in August 2010.

Challenging conditions continued to present opportunities to deploy ELH technology. Operators requested increased capabilities to deploy cemented liners and standalone applications in horizontal wells, which requires reliable tools to wash and ream to the bottom, rotate at higher torques for cement distribution in the well, and the capability to isolate a highly deviated top of liner (TOL). High-torque ELH systems addressed these challenges. In 2011, the first high-torque tool was used to install an ELH in Colombia. The technology was highly received and adopted into all Halliburton ELH operations in the country.

ELH technology is a must-have solution when the capability to cement and expand with the absence of return flow at the surface is necessary, or during operations that involve high-performance fluid to mitigate losses. Halliburton ELHs continue to execute and succeed under these conditions.

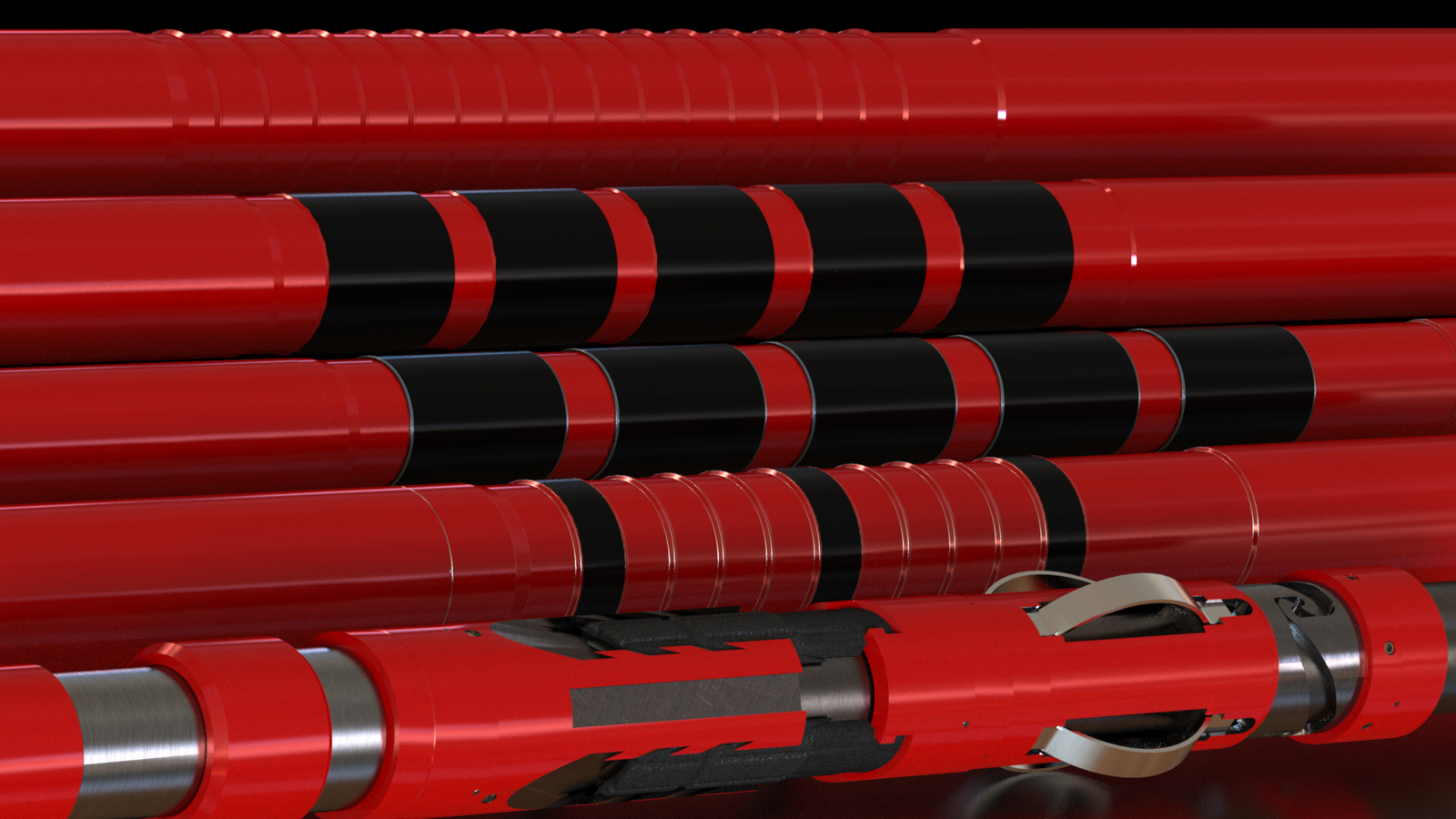

Currently, ELH technology is used for operations in extended-reach wells that require higher torque values be managed at the surface, managed pressure drilling and/or cementing during liner hanger deployment, deepwater wells in remote areas more than 7,000-ft deep, and operations where rotation and reciprocation while cementing is necessary.

installations

job efficiency rating for operations

job efficiency over the last 5 years

By 2023, the number of installations performed in Colombia using Halliburton ELH technology reached more than a thousand, this number continues to grow. The overall job efficiency rating for operations performed in the country is 97% and 98% over the last five years.This was achieved with at least 61% of operations requiring washing capabilities running in hole (RIH) and 44% requiring both washing and reaming capabilities. The deepest expansion record to date was achieved in November 2023 during a 7 × 9 5/8-in. system installation with a 18,033-ft TOL and 22,343-ft liner shoe.

XtremeGrip expandable liner hanger systems

High-performance metal-to-metal sealing technology ideal for complex deepwater wells and ultra-high temperatures for geothermal applications.

Product InformationVersaFlex® Expandable Liner Hanger System

The industry’s first fully engineered ELH system designed for use in land, offshore and deepwater applications.

Product Information

Halliburton liner hanger portfolio includes expandable and conventional options for mature, unconventional, deepwater, and geothermal applications.