Search

Search

Search

Search

Halliburton performs first-ever circumferential ultrasonic cement evaluation in 1-in. casing for Petrobras

Download PDFDeep Water

Properly perform and assess cement evaluation of thicker, new casings

Deepwater, Brazil

Recent advances in deepwater exploration technology and operational strategies have allowed oil and gas operators to reach more complex and challenging fields. One advance is the use of more resistant casings to support demanding conditions like temperature, pressure, and reservoir contaminants throughout the life cycle of the well. This increase of resistance in casings is primarily a result of changes in metallurgy and heavier linear weight, which in turn increased casing wall thickness. This new solution created a new problem for operators and service companies — how to properly perform and assess cement evaluation of these thicker new casings?

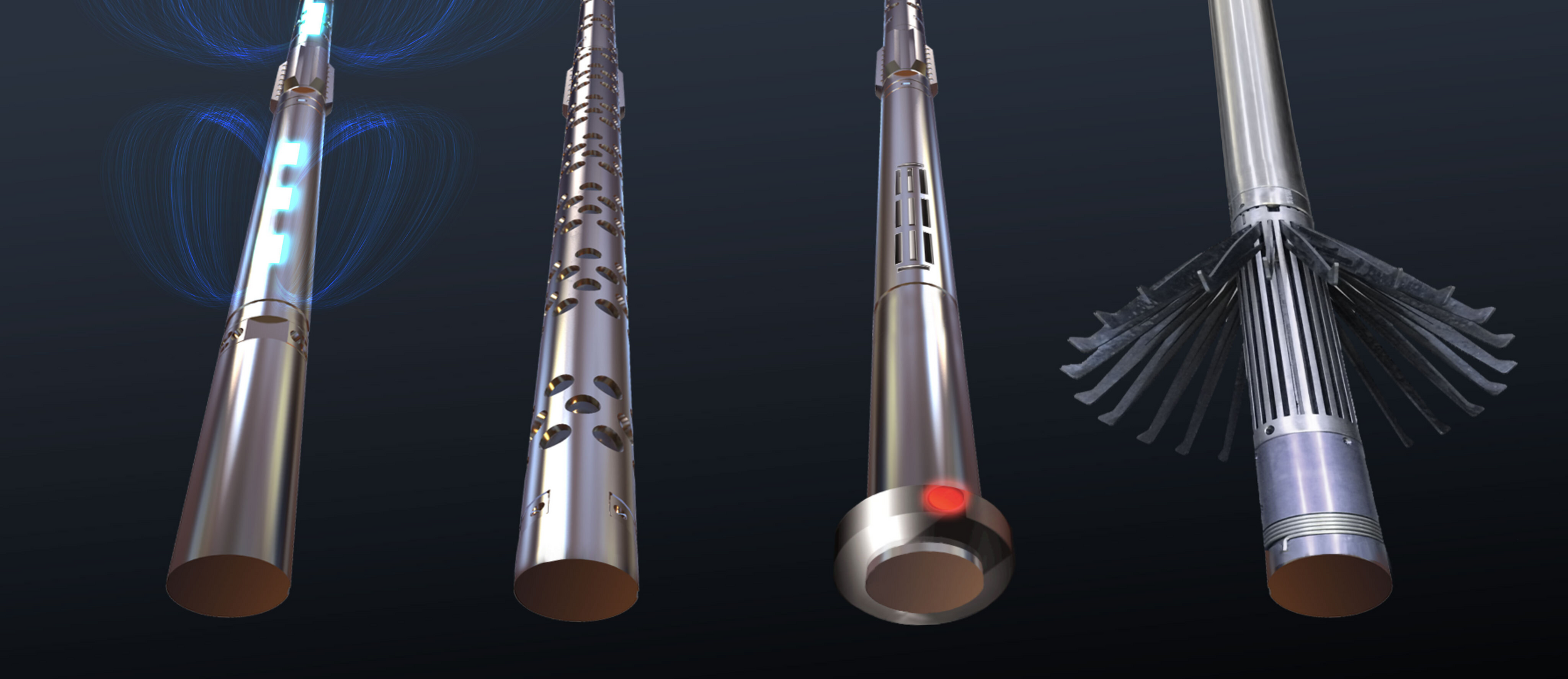

Driven by the demand for more reliable and accurate answers for cement evaluation in highthickness casings, Halliburton developed the Circumferential Acoustic Scanning Tool-Extended Range (CAST-XR) tool, allowing reliable ultrasonic measurements to be obtained in all types of cement systems (conventional, ultralight, foam, resin) in casings with thicknesses greater than 1 in. The CAST-XR tool significantly increased the operational limits for circumferential ultrasonic cement and casing inspection measurements to provide the best possible answers in terms of zonal isolation and well integrity — from the drilling stage to the permanent abandonment of the well.

As a vital part of well construction, cement evaluation logs are required to verify zonal isolation and well integrity. According to regulations and industry best practices, the ideal way to perform this evaluation is through sonic-ultrasonic combo logs, which have independent and complementary measurements that provide full-hole coverage to determine cementing job quality, channeling, and casing integrity, to name a few. Until recently, the available circumferential ultrasonic technology couldn’t operate in conditions where casing walls were greater than 0.75 in., thus limiting the quantity of information that could be registered and increasing well integrity uncertainty in this new scenario.

Beneath more than 7,000 ft of water, Petrobras had a deepwater well that needed sonic and ultrasonic measurements to perform a full cement evaluation in 10¾-in.-thick wall casings. The casings were 85.3 lb/ft (0.8-in. thick) and 109 lb/ft (1.0-in. thick).

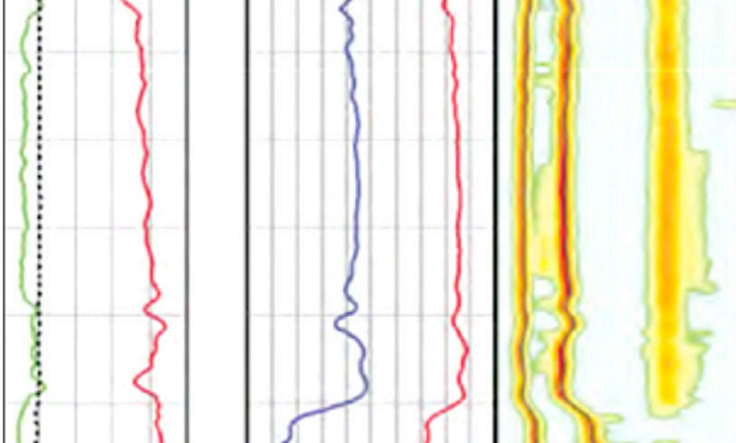

This well was carefully selected because it had both free and cemented pipe in the thick casing section in order to evaluate the dynamic range of the tool in the presence and absence of cement.

Halliburton recommended its CAST-XR tool, which integrates a state-of-the-art low-frequency transducer for highfidelity signals, special hardware and firmware, and an impedance algorithm to evaluate cement through thicker casings. It operates in mud systems that are a barrier to older technologies. These past obstacles were heavy mud weights, high content of solids, and a thick casing wall. The technology in the CAST-XR tool breaks down these barriers for a robust and reliable cement and pipe wear/condition evaluation in extreme conditions.

Technology and operational teams worked closely together on the planning of this service. Tool setup and logging parameters for given well conditions were selected with the use of proprietary CAST™ planner software. The tool performed a shop log routine in which the tool is placed in a test fixture or casing with material of different impedances in the annular section to verify proper tool response. Finally, the CAST-XR tool was deployed in combination with the Borehole Compensated Sonic Array Tool (BSAT™) service to acquire cement evaluation and casing inspection data. Two different casing thicknesses were logged in the same pass, acquiring an effective circumferential ultrasonic cement evaluation answer in both casing weights.

successfully logged 1-inch thick casing

operation in the world to provide these results

From the CAST-XR/CBL combination, Halliburton was able to generate the first sonic-circumferential ultrasonic combo log for cement evaluation, simultaneously providing cement and casing integrity data in 1-in.-thick casing. Remarkably, this was the first operation in the world to ever provide an effective circumferential ultrasonic cement evaluation and pipe-inspection answer in 1-in.-thick casing. The technology exceeded expectations in operational effectiveness and customer satisfaction.

In a country like Brazil, where 94% of the oil production comes from offshore fields and where the hydrocarbon production from presalt fields has nearly doubled in only two years, the ability to assess well integrity information through cement evaluation of thick casing is of paramount importance.

Addressing the toughest issues in well intervention, Halliburton offers services to extend well life, improve performance, and limit downtimes.

Halliburton designs and delivers dependable barriers tailored to minimize risk and maximize production.

The BSAT tool provides acoustic formation properties and cement evaluation information.