Search

Search

Search

Search

A 420 Corsair™ EMS motor coupled with Tiger Shark® TS3 pumps provided the power needed to increase drawdown by 12% and total fluid production by 15%

Download PDFUnconventionals

Tight clearance between ESP motor OD and casing ID increases risk

Permian Basin

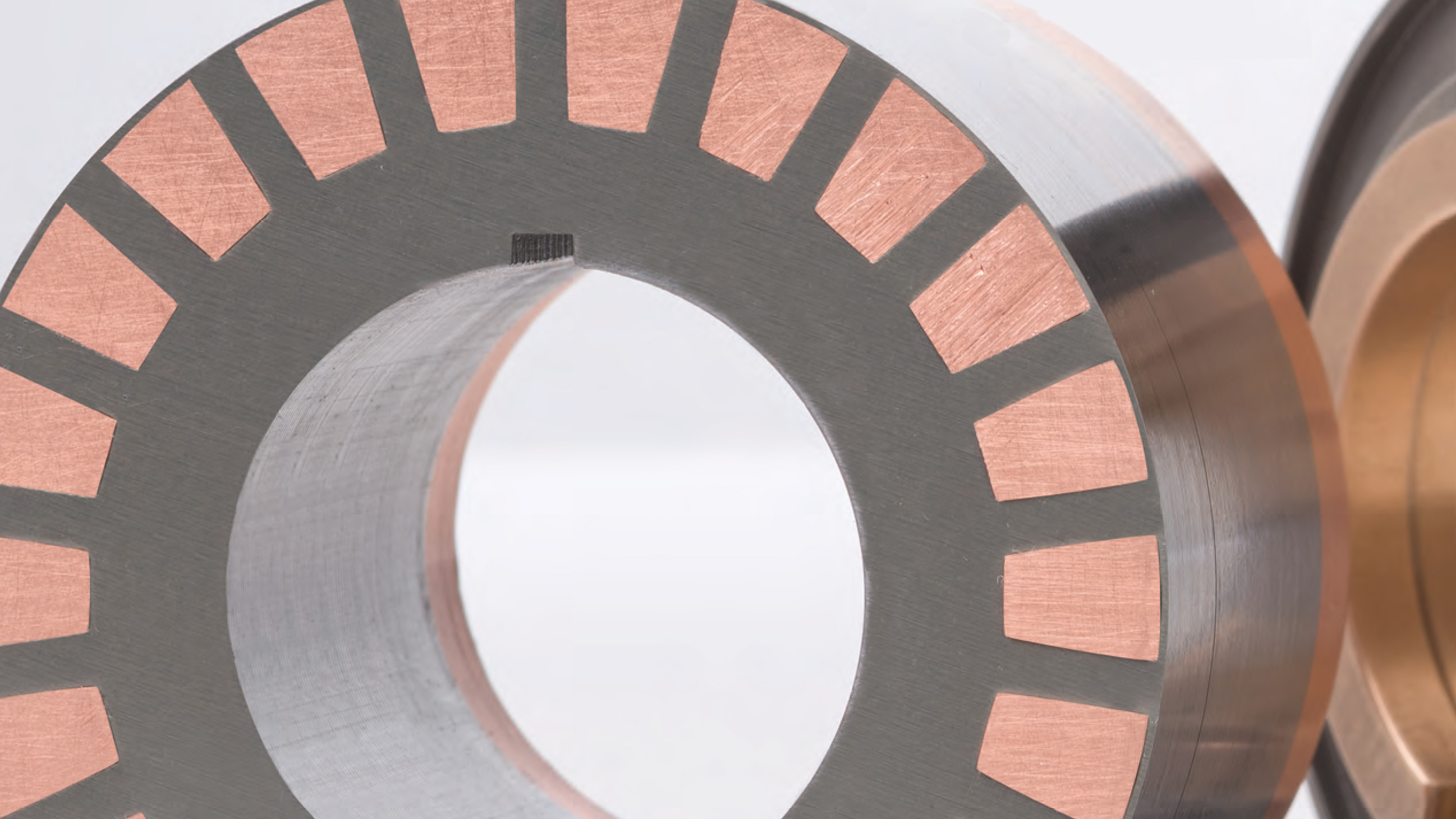

420 Series Corsair motor features:

North American operators have begun completing unconventional wells with 5-1/2-in. “long string” production casing run to surface instead of the traditional 4-1/2-in. liner. “Heavy wall” (20-23 lb./ft) casing is used because it is better suited than lighter wall casing for fracking and completions.

The move to running 5-1/2-in. heavy wall casing creates several potential issues because of tighter clearances between the outer diameter (OD) of the electric submersible pump (ESP) systems typically designed for these applications and the smaller internal diameter (ID) of the thicker wall casing. During installation, tighter clearances increase the possibility of damage to the MLE cable and ESP equipment. During operation, the smaller flow area around the motor leads to increased fluid velocity, pressure, and the potential for scale build-up and motor cooling issues. Tighter clearances also make overshot retrieval of equipment more difficult.

Smaller motor designs have better clearances but may not provide adequate power or maybe too long in tandem configurations for the tangent section. Permanent magnet motors (PMM) can provide higher power ratios in smaller diameters but have experienced dynamic load failures and can be a safety hazard during maintenance.

We designed a 420 Series Corsair motor that provides:

Increased production revenue over 11 days

Increased drawdown

Increased production

Increased monthly production revenue

For one operator, a 420 Corsair™ EMS motor coupled with Tiger Shark® TS3 pumps was installed on the same pad as another well in which a larger diameter system was installed. Both wells had a similar productivity index rate and water cut. The 420 provided the power needed to increase drawdown by 12% and total fluid production by 15% compared to the larger, traditionally sized equipment.

Multiple products increased production

Corsair motors deliver long run times with greater reliability by actively resisting temperature and deformation in the harshest conditions.

Tiger Shark® electric submersible pumps are designed to adapt to changing well production, improving operating range and run life in harsh environments.

Avenger® MLE provides increased reliability in high-temperature, highly corrosive gassy wells.