Search

Search

Search

Search

The Intelevate platform was deployed to provide cloud-based, remote well-monitoring and optimization solutions, eliminating in-person wellsite visits.

Download PDFUnconventionals

Customer could not fully optimize ESP performance and run life.

Oklahoma

The Intelevate platform team monitored, modeled, and analyzed data and made several recommendations, including optimal VSD operating modes and bi-weekly KPI meetings and installing our Hydro-Helical Gas Separator and SandRight Solids Fallback preventer.

Operators producing wells with electric submersible pumps (ESP) face the challenge of choosing and iterating on designs for optimal production. Some rely on field technicians with specific ESP experience, which can add expense. These technicians may not have in-depth knowledge about all aspects of each vendor’s ESP equipment and optimization methods.

A customer with operations in Oklahoma faced recurrent ESP shutdowns, as often as every four hours, due to gas-liquid ratios (GLR) up to 750 scf/stb. Because the customer’s field operators did not have practical experience managing and optimizing ESP equipment using variable speed drives (VSDs) or regularly evaluating installed equipment, they could not fully optimize ESP performance and run life. The issue was exacerbated due to increased preventable shutdowns and decreased oil production. Finally, there was no regular integration of improvement opportunities once failed ESP equipment was analyzed.

The Intelevate platform was deployed to provide cloud-based, remote well-monitoring and optimization solutions, eliminating the need for in-person wellsite visits. Our team analyzed and modeled the customer’s data and recommended the following actions: audit VSD set points, set optimal VSD operating modes, flush jobs, and surface valve adjustments, deadhead and tubing integrity tests, power consumption optimization, and bi-weekly meetings to achieve target key performance indicators (KPIs).

The team also recommended equipment upgrades to address production issues:

Since using the Intelevate platform’s 24/7/365 remote monitoring service, the customer has experienced more consistent production, reduced downtime, and reduced onsite troubleshooting costs. The customer has been satisfied with the value delivered by the Intelevate platform and is planning to increase the number of active wells being monitored.

Reduced costs for onsite troubleshooting per year

Miles driven by field personnel reduced

Hours of increased uptime

Different technologies used to increase production

Multiple products and solutions increased production

Providing enhanced ESP system optimization and extensive customizable well monitoring to meet all your production needs

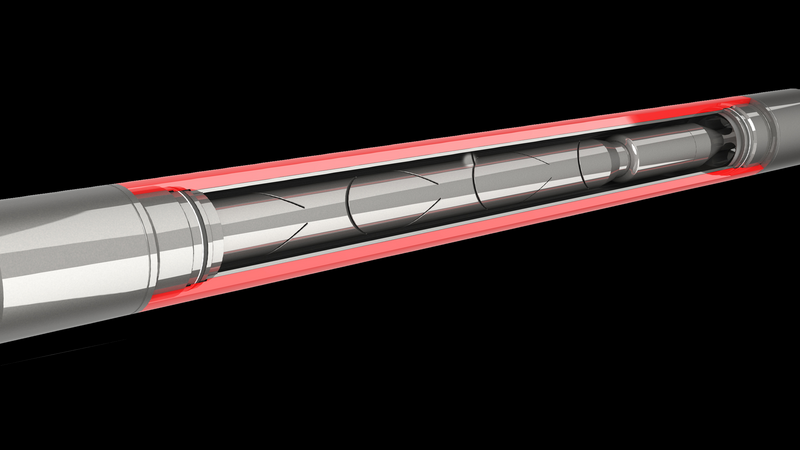

The Hydro-Helical® gas separator sets a new industry standard for flow rate, performance, and reliability.

The SandRight® tool prevents solids from entering the ESP system during shutdown events, eliminating overstressed motors and accelerated pump wear when restarting the system.