Search

Search

Search

Search

Innovative solution drills one of the longest slim sections (5,500 Feet) on Norwegian Continental Shelf

Download PDFMature Fields

Run one of the longest slim-hole drilling operations using the Geo-Pilot® RSS

Norwegian Continental Shelf, North Sea, Norway

In a mature field on the Norwegian Continental Shelf of the North Sea, an operator had attempted twice to drill a new extended-reach drilling (ERD) wellbore with a 2.05 measured depth (MD) to true vertical depth (TVD) ratio that resulted in the bottomhole assembly (BHA) becoming lost in hole above the reservoir. The operator engaged Sperry Drilling to meet the goal of drilling and geosteering a 5¾-inch section with a complex BHA through the reservoir to the hydrocarbon reserves, with the need of a quick turnaround solution. In only three days, Sperry Drilling designed and mobilized a drilling system engineered to address the reservoir challenges and meet the operator’s goal. By partnering with Sperry Drilling, the operator drilled more than 5,500 feet (1,676 meters) in one run, and achieved its goal of reaching the hydrocarbon reservoir without incurring nonproductive time (NPT).

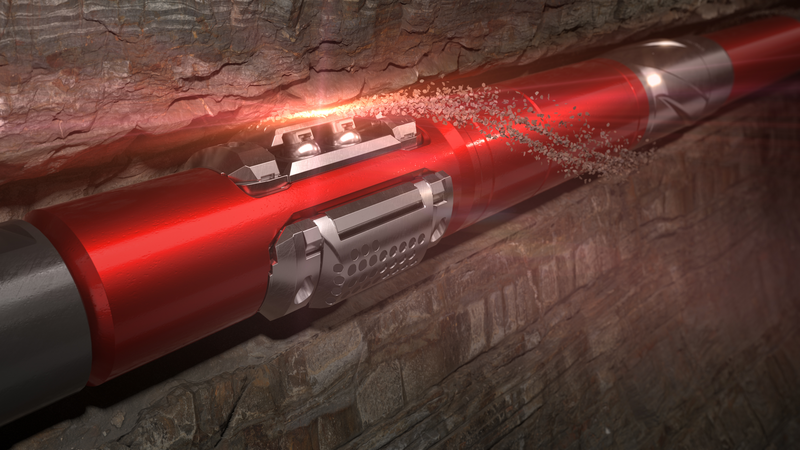

In the previous operation of this ERD well, an expandable liner had been set to address formation instability. This expandable liner created a challenge, since the liner’s internal diameter was only 5.795 inches, which is extremely narrow. The wellbore’s narrow opening required a slim-version drill bit and the rotary steerable system (RSS) BHA also had to be engineered to successfully pass through this narrow opening in order to reach total depth (TD). An opening this narrow presented quite a challenge because the smallest wellbore size that Sperry Drilling had ever drilled with an RSS BHA was 5 7⁄8 inches in diameter. This would be the first time globally that Sperry Drilling had ever drilled with an RSS BHA in such a small 5¾-inch wellbore size. Another challenge for this operation included designing an RSS BHA with the right size of logging-while-drilling (LWD) stabilizers that would still be reliable and capable of logging the section. Additionally, the Sperry Drilling team had to mobilize with this newly engineered solution within a very short time frame. Not only did the operator needed to drill and log this small-hole section, but the operator also needed to run a 5-inch liner to complete the well.

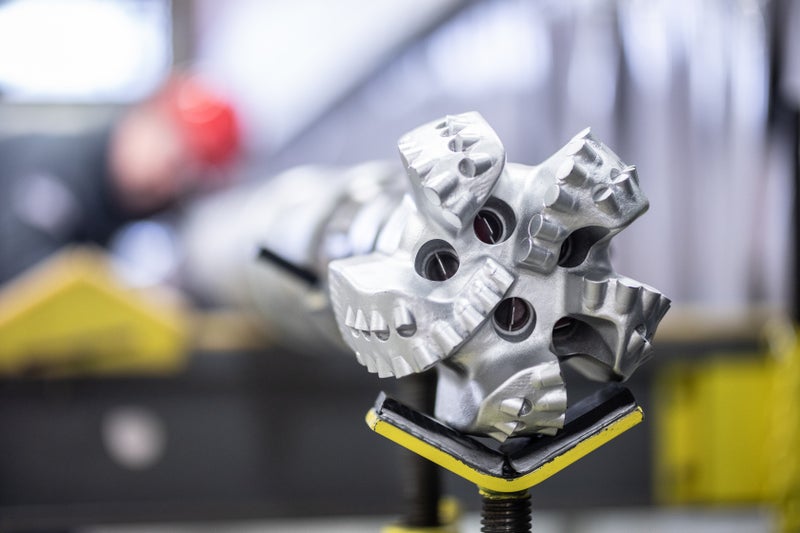

Sperry Drilling applied the strength of its worldwide network of products and expertise to provide a solution for this narrow opening. In only three days, the Sperry Drilling team designed and mobilized a drilling system, including a 5¾-inch Halliburton polycrystalline diamond compact (PDC) drill bit that was flown in from another location. The Geo-Pilot® RSS parts required specifically for the 5¾-inch hole size were brought in from the U.S., and LWD stabilizers were modified locally.

All products and services were hand-selected for their suitability for this specific application. With the Halliburton 5¾-inch drill bit, Sperry Drilling used a reamer to open the hole to a 6½-inch diameter.

In addition to the 5200 Geo-Pilot RSS, Sperry Drilling used quad-combo LWD tools to provide all the measurements needed while drilling – including azimuthal density, neutron porosity, gamma, azimuthal deep resistivity, pressure while drilling (PWD), downhole weight and torque on bit, and formation pressure points from ALD™, CTN™, DGR™, ADR™, PWD, DrillDOC®, and GeoTap® sensors respectively.

Sperry Drilling also included the Drilling Engineering Solutions (DES) with Applied Drilling Technology (ADT® service) specialists from an onshore operational center to monitor and advise on drilling operations and parameters in real time for improved drilling efficiency. The optimization team also used the StrataSteer® 3D geosteering service and MaxBHA™ software in order to model and advise on the stabilization of the 5-inch liner run to TD.

Global 5¾-inch Hole Size Run with Geo-Pilot® RSS

Circulating Hours

Feet Total Depth (TD) Drilled

Through its partnership with Halliburton Sperry Drilling, the operator reached the targeted reservoir – meeting the goal by successfully drilling a new ERD well that reached 20,500 feet (6,248 meters) TD. The Sperry Drilling team met the challenge of the narrow liner opening and then drilled 5,510 feet (1,679 meters) from 14,900 feet (4,542 meters) to 20,500 feet (6,248 meters) TD in one run in 236 circulating hours. The operator achieved one of the longest runs on the Norwegian Continental Shelf with a slim RSS, and was the first to drill a 5¾-inch wellbore with a 5200 Geo-Pilot® RSS.

By successfully drilling and running the 5-inch liner to TD in this challengingly small hole size, the operator will now be able to produce from this well that may have not been possible without collaboration and teamwork from Sperry Drilling to engineer and design the BHA. Sperry Drilling found an innovative way to move beyond the limitations of a narrow wellbore and to deliver a productive well for the operator. Whenever there is a need to drill a 5¾-inch slim section, Sperry Drilling has an optimal solution – proving that, with collaboration and expertise, Sperry Drilling can provide suitable drilling solutions for complex challenges.

Halliburton delivers drilling performance to increase asset recovery, improve wellbore quality, and reduce overall well construction costs.

The Halliburton Geo-Pilot® rotary steerable systems (RSS) is designed to deliver unprecedented speed and precise steering.

Fixed cutter and roller cone bits are engineered to optimize performance by using our global network of engineers to design the right bit for the right application.

Halliburton rotary steerable systems are engineered with advanced technologies to reduce well time and accurately place well in reservoir.

Gather real-time, high-quality data while drilling for improved subsurface insight, increased ROP, and enhanced wellbore stability.

Halliburton integrates cutting-edge technologies into drilling and completion projects to help efficiently achieve client operational and financial goals.