Search

Search

Search

Search

B-Annulus pressure/temperature monitoring

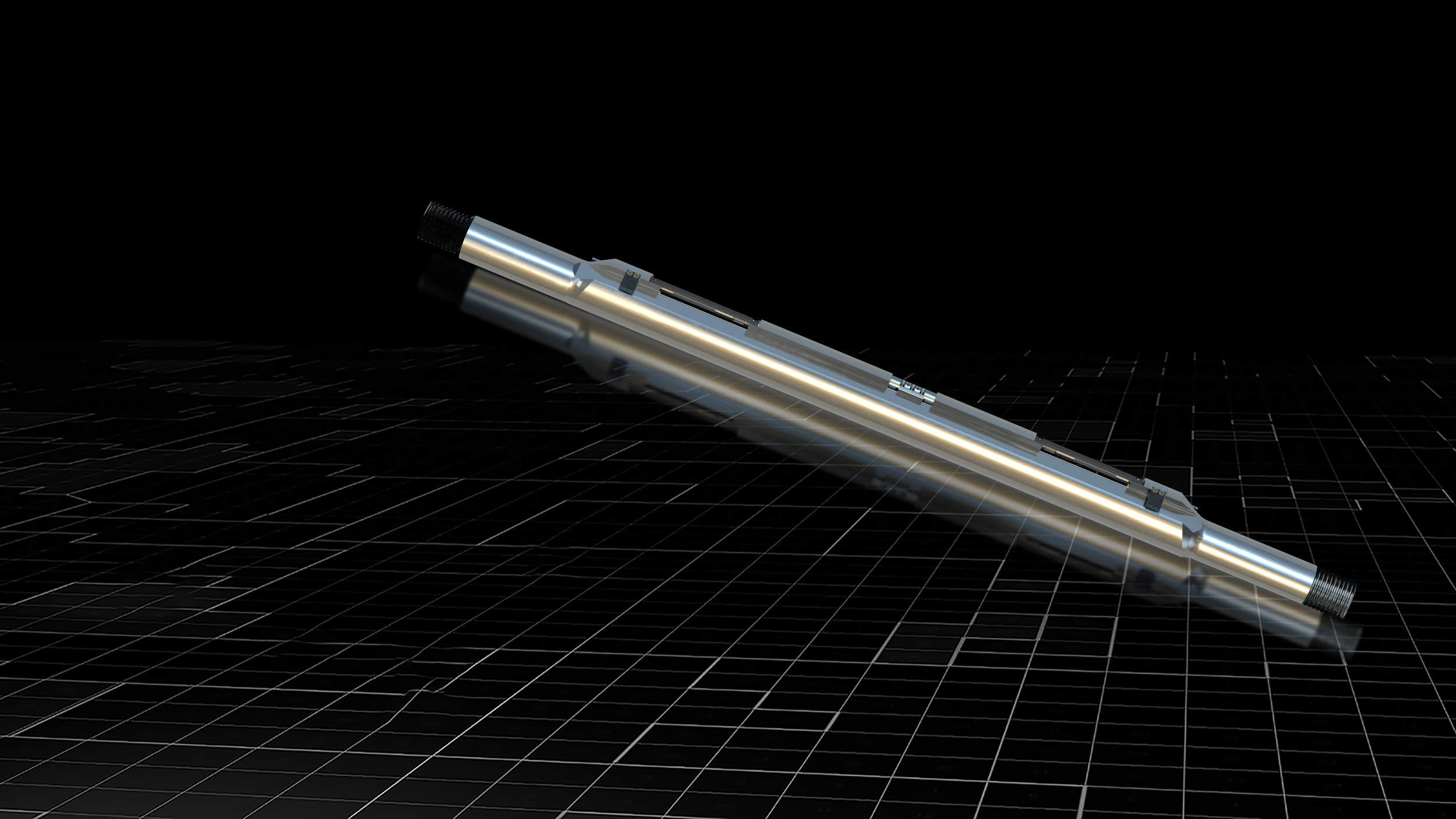

Talk to an expertOperators are increasingly under pressure to reduce costs while maximizing the safety and control of their wells. Optimizing flow to casing design limitations and subsequently monitoring wellbore integrity over a well’s lifetime are more critical than ever before. The ability to continuously monitor for leaks and operator-induced pressures behind casing has not been possible on subsea wells. Well integrity is verified periodically at the expense of production, flow is often restricted due to casing design limitations, and casing designs have costly safety factors. When barrier integrity is compromised, costly workovers or plug and abandonment (P&A) may be the only alternatives. The DataSphere® LinX® monitoring system is a step change in well integrity monitoring enabled by wireless through-casing power and communication. With the LinX system, sensors are continuously communicating from behind the well barriers – right where they need to be – without compromising well integrity or changing the well design, and without major revisions to the drilling program.

Modern downhole pressure and temperature technology for low-carbon solutions

Accurate monitoring for production applications

Reliable, real-time monitoring of downhole conditions

Reduce operational risks and costs associated with production logging runs

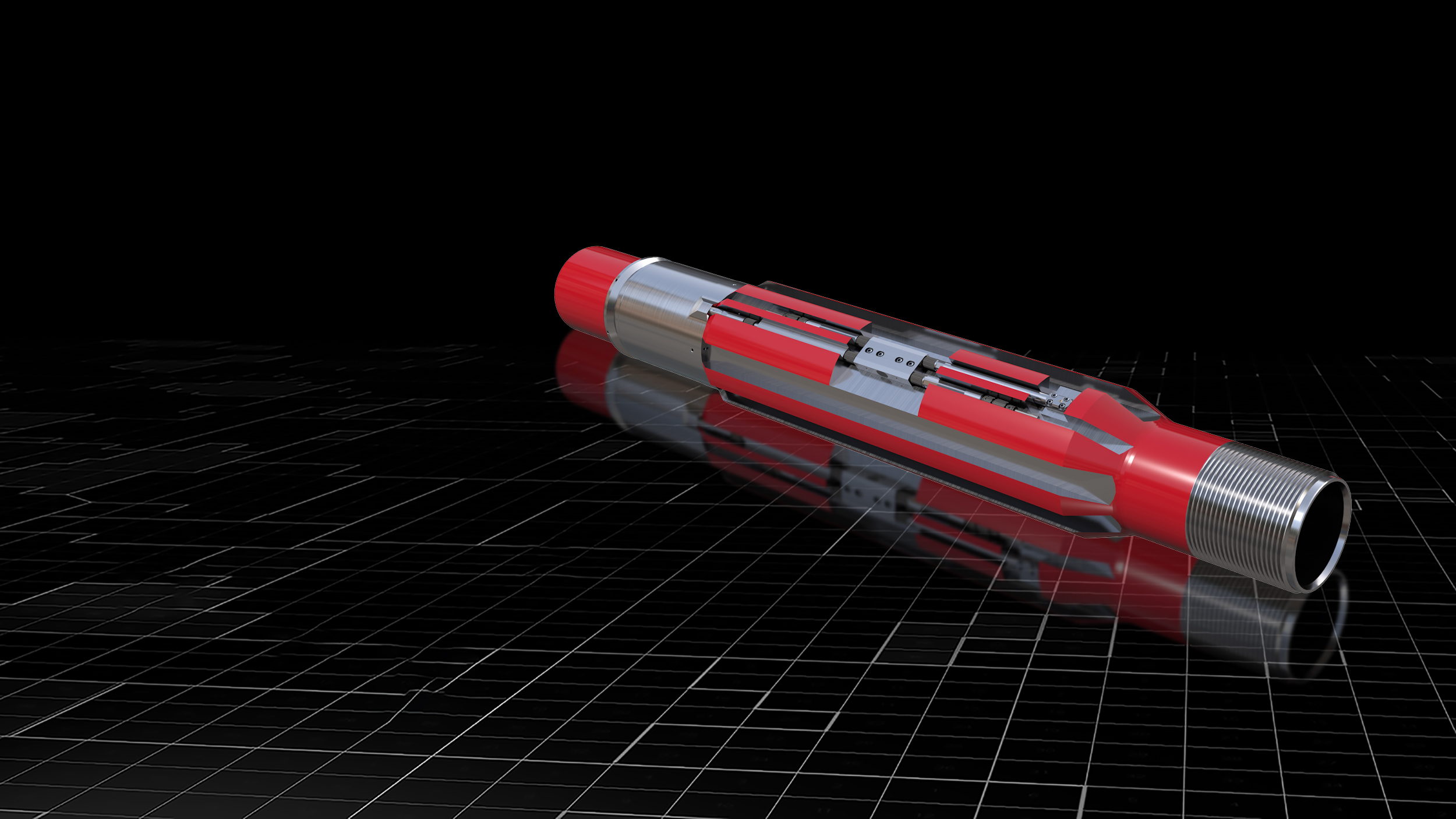

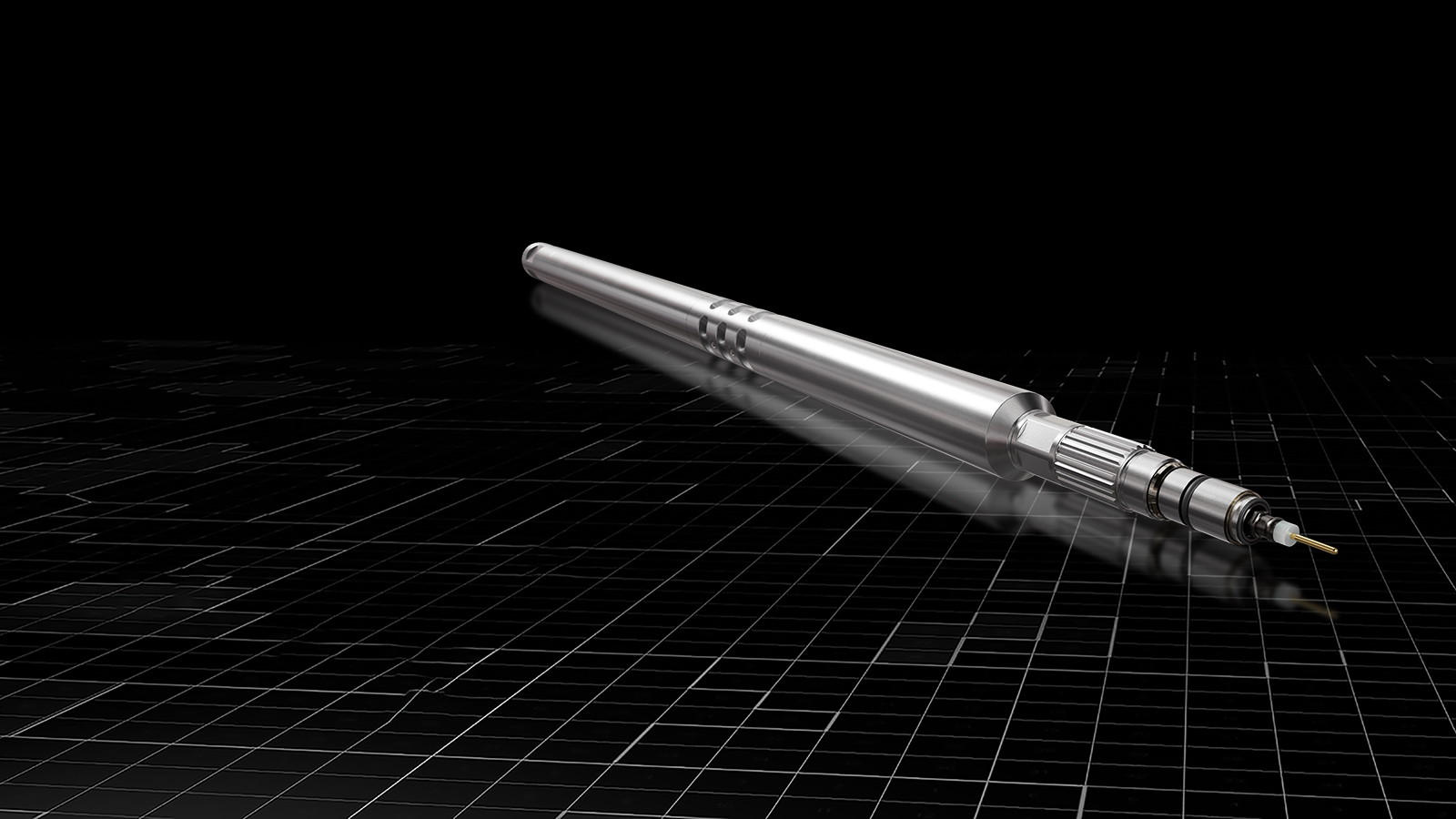

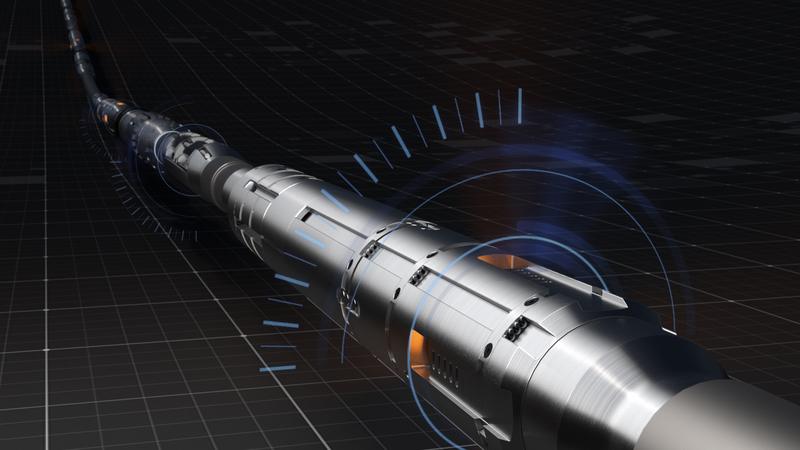

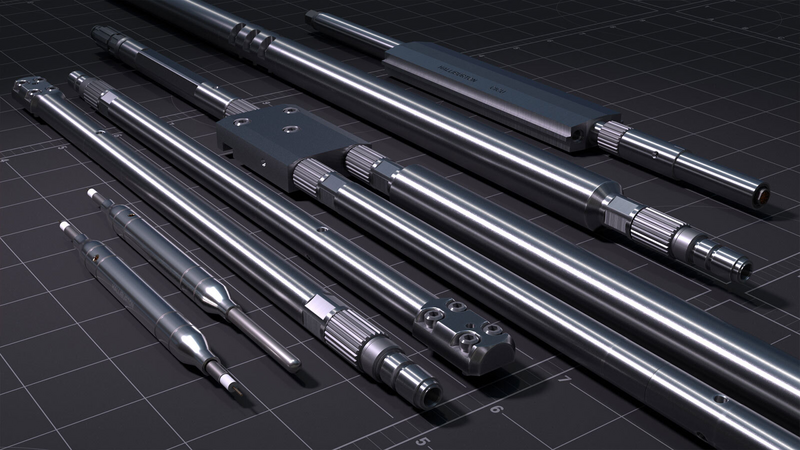

The LinX monitoring system is a wireless through-wellbore technology that enables the placement of a permanent pressure/temperature gauge behind the production casing in Annulus-B. The system uses electromagnetic power and communication to drive and communicate with sensors without the need for batteries or extra barrier penetrations. Power down hole and communication with the surface is provided by industry-standard cable and an IWIS interface card, enabling the LinX system to be combined with traditional downhole monitoring on a single cable.

Today’s subsea wells have enclosed volume in the B-Annulus, which is prone to operator-induced pressure buildup due to temperature changes induced by the flow. Many of today’s subsea wells make use of the A-annulus for gas injection, moving the barrier from the A- to the B-annulus. This makes managing the pressure integrity of the wellhead more complex since the B-annulus on subsea wells is sealed off at the wellhead. The system picks up any pressure/ temperature fluctuations, enabling the operator to detect pressure buildups while producing. This new knowledge drives revenue up, while less costly casing programs drive CAPEX down, thus helping ensure safe operation of the well and reducing the risk of costly interventions and non-productive time

LinX system B-annulus monitoring is a three-step process powered by electromagnetic currents powering quartz pressure and temperature (P/T) gauge sensors.

The electromagnetic transfer of power, does not have the limitations of batteries, enabling unlimited transfer of data over the life of the well as needed for permanent monitoring

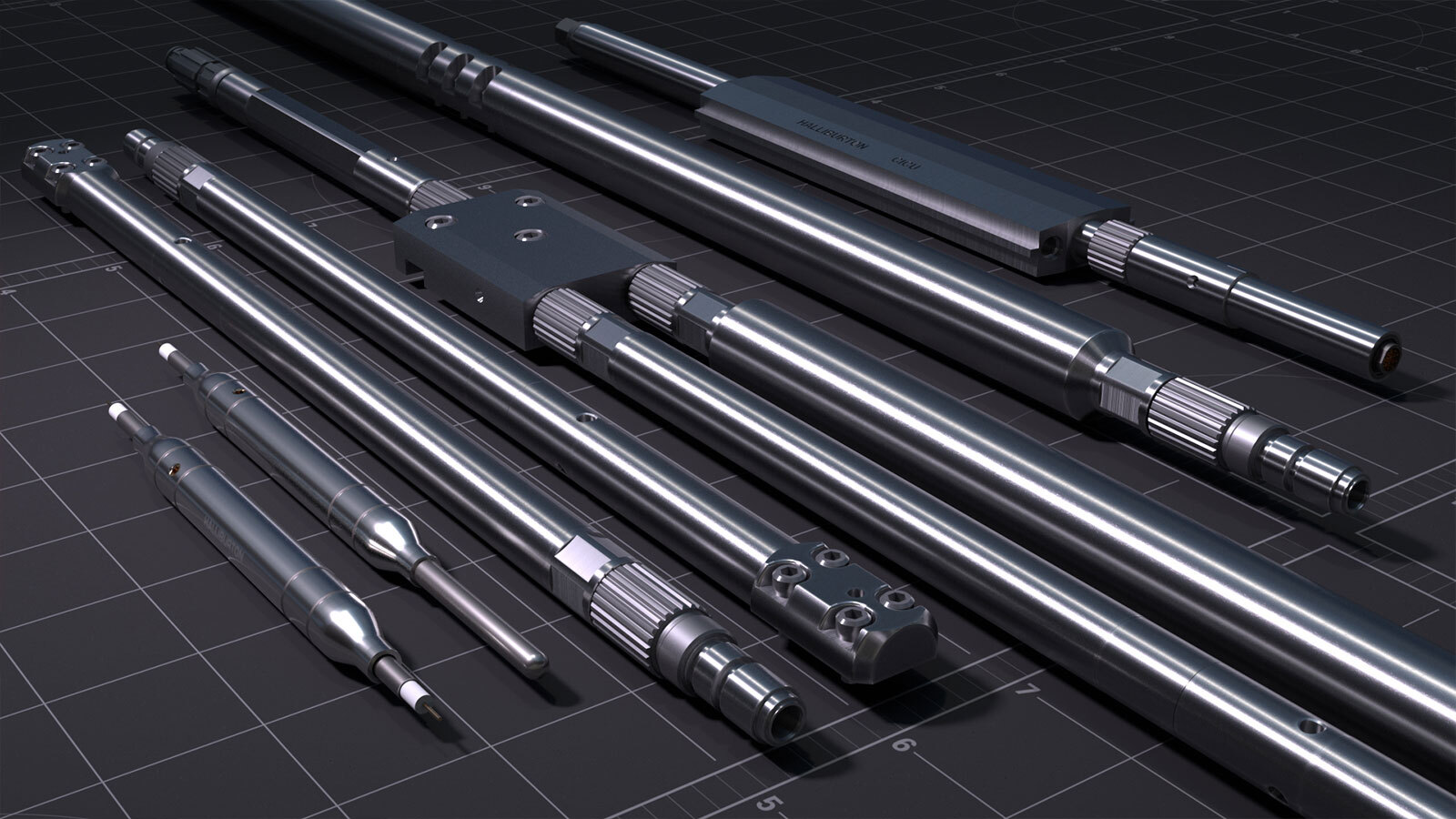

Halliburton SmartWell® completion systems allow you to collect, transmit, and analyze completion, production, and reservoir data and control and monitor selected reservoir zones remotely and in real-time.

The DataSphere permanent monitoring suite is a robust combination of the best in sand control, multilateral and intelligent completion technology.