Search

Search

Search

Search

Improve reservoir management through control of produced or injected fluid

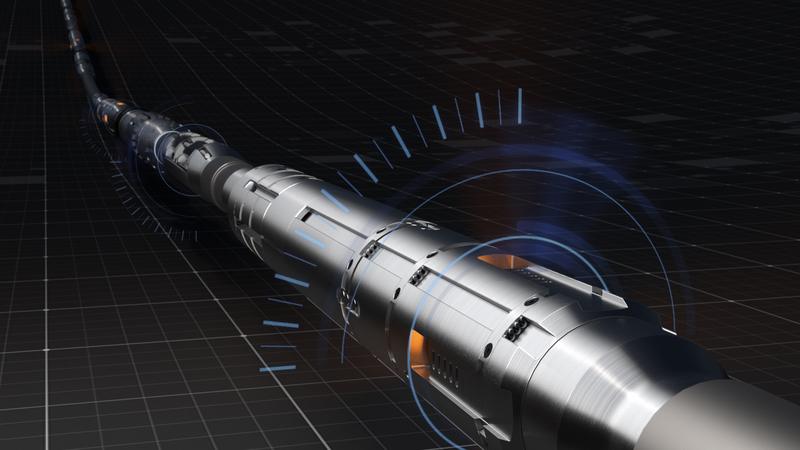

Talk to an expertThe Accu-Pulse™ module enables incremental opening of a multi-position interval control valve (ICV) to control produced or injected fluid rates for enhanced reservoir management. The module works in tandem with either the Halliburton Digital Hydraulics™ system, direct hydraulics downhole control systems, and/or with the HS-ICV multi-position valve.

The Accu-Pulse control module provides incremental movement of a suitable ICV flow trim by exhausting a predetermined amount of control fluid from the ICV control piston. The ability to repeatedly recharge and exhaust the same amount of fluid allows the ICV flow trim to move accurately through up to 11 predetermined positions.

The Accu-Pulse control module can communicate with either side of the ICV piston and drive the ICV open or closed. This provides incremental positioning in one direction, with the ICV being driven to a fully open or closed position when pressure is applied from the other direction.

Next-generation electro-hydraulic control system delivers fast, precise, bidirectional choke control and manages up to 12 ICVs using only three control lines

The direct hydraulics downhole control system uses direct hydraulic control lines from the surface to remotely actuate downhole flow control devices.

The SmartPlex® II downhole control system is an electro-hydraulic multi-drop system that provides reliable zonal control of multiple valves in a single wellbore.

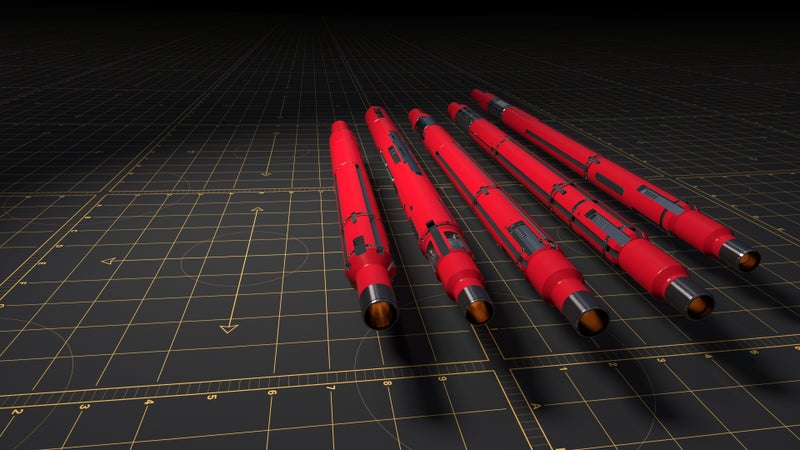

The debris-tolerant HS interval control valve (HS-ICV) enables deployment of Halliburton SmartWell® systems in high-pressure, deepwater environments.

Halliburton SmartWell® completion systems allow you to collect, transmit, and analyze completion, production, and reservoir data and control and monitor selected reservoir zones remotely and in real-time.

Halliburton intelligent flow control systems provide a method to integrate manual or automated surface control systems with downhole SmartWell® completion equipment.