Search

Search

Search

Search

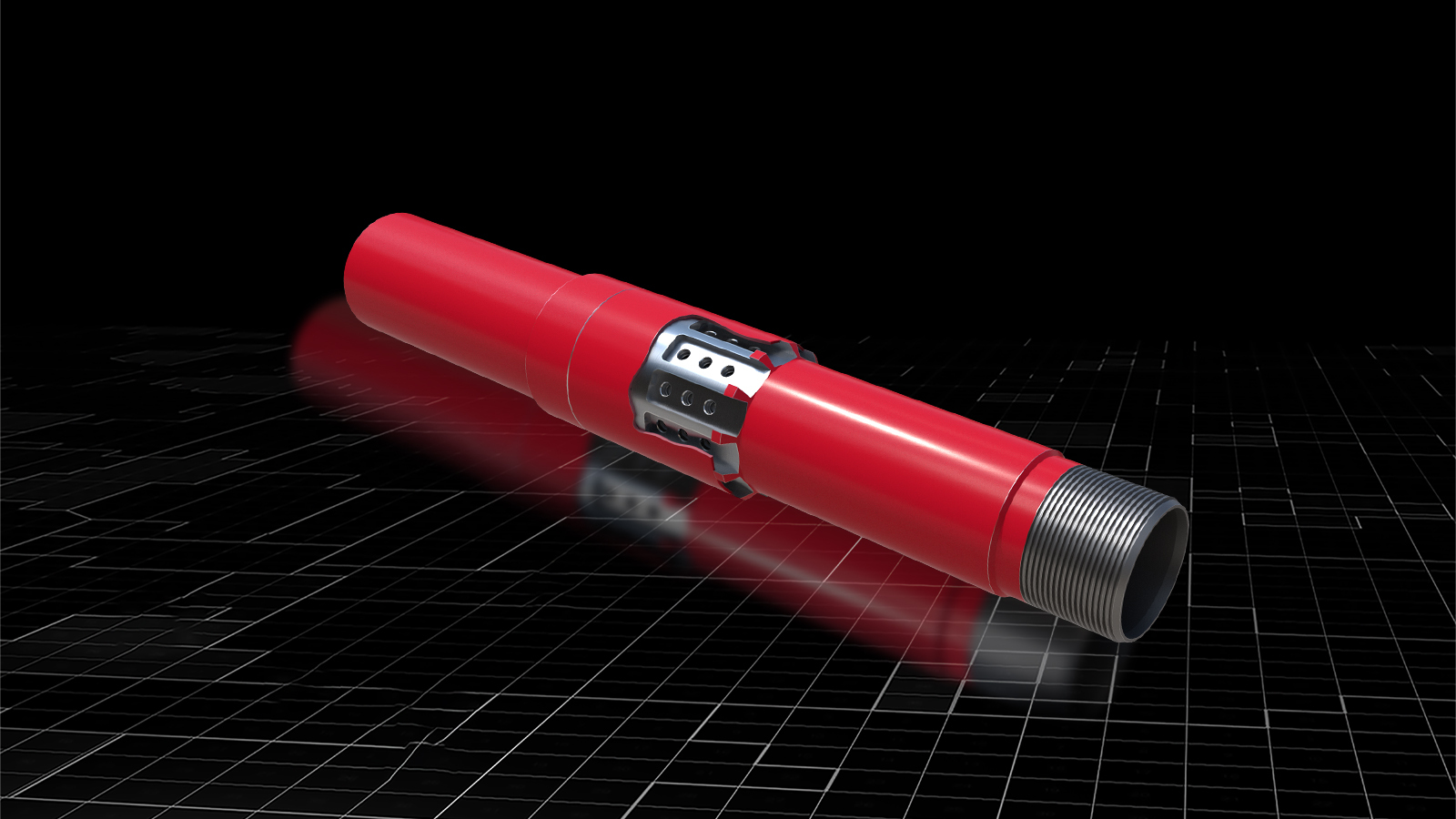

ICD completion with mechanical isolation plugs

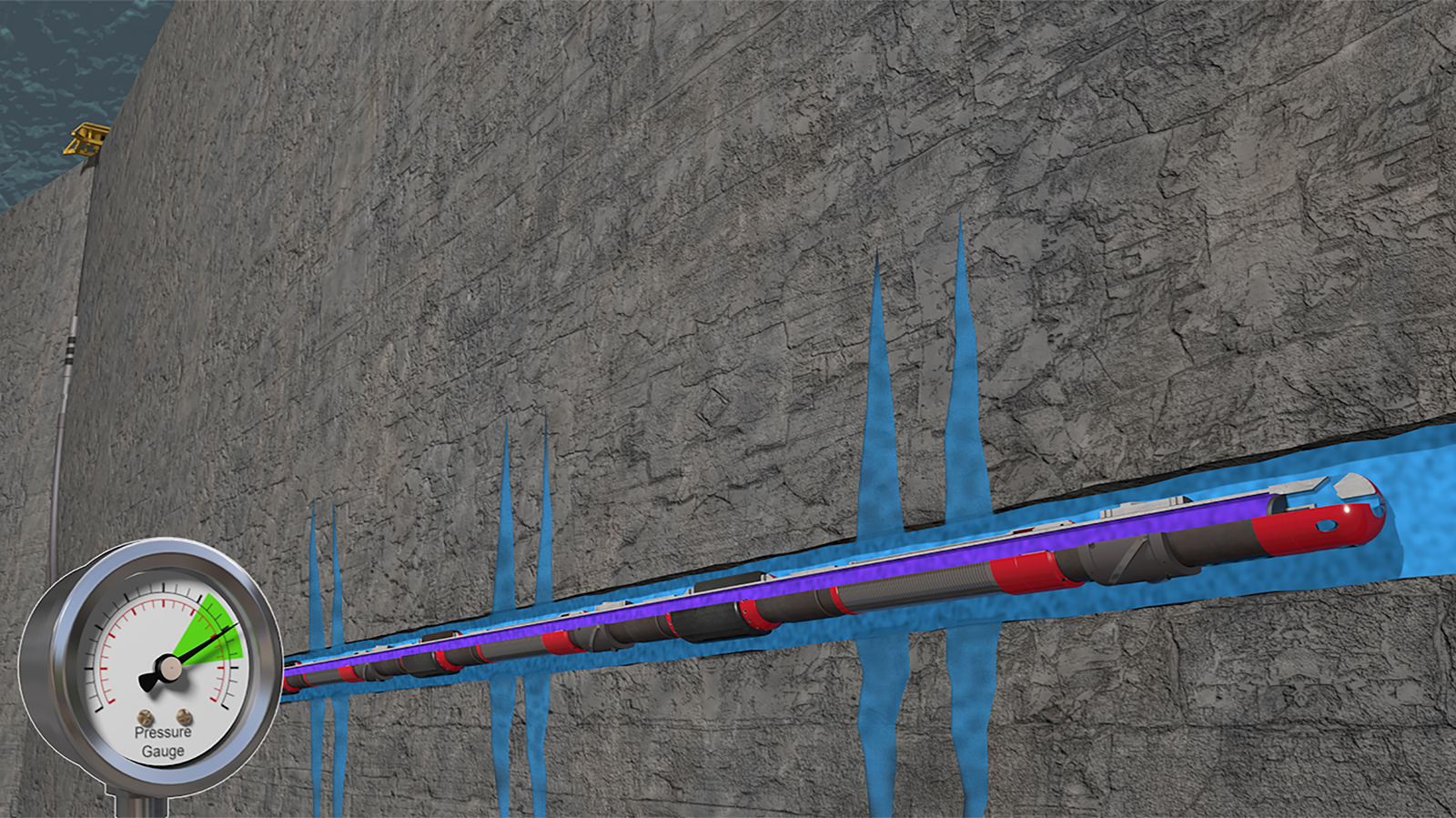

Talk to an expertCompletions with inflow control devices (ICDs) are designed to balance flow in injectors and producer wells. The balanced flow contributes to the delay of water and gas breakthrough and extends the life of the well. ICD completions also have the potential to increase total oil recovery.

These ICD lower completions are traditionally deployed with washpipe or an inner string to accommodate effective fluid circulation, displacement, and washdown capability. While this functionality offers multiple benefits, the following points should be considered:

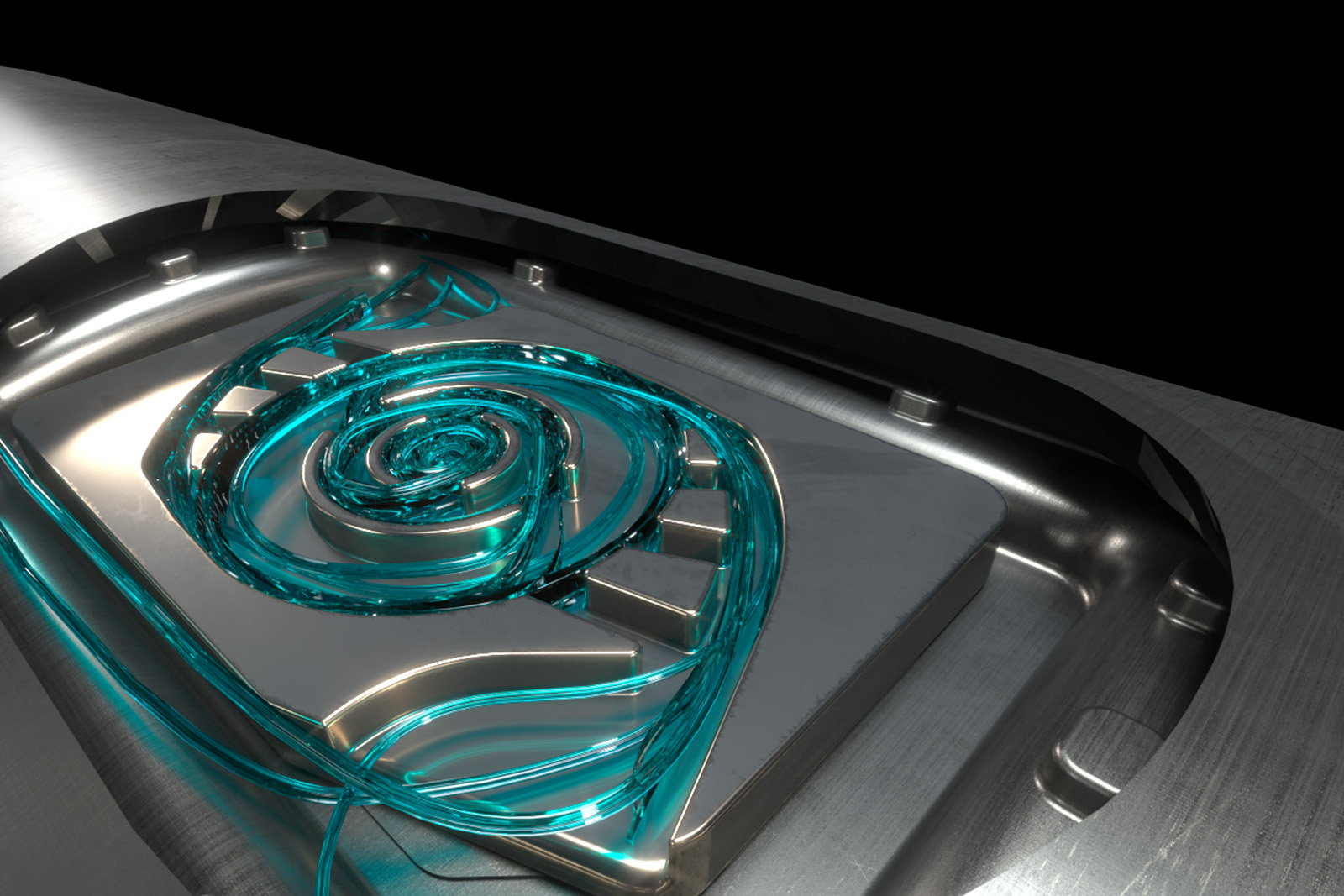

The innovative EquiFlow washpipe-free adjustable AICD uses blanking plugs to adjust the flow settings through the device. Dissolvable plugs are an option to block the flow paths to the AICD at the basepipe perforations and disappear after the completion is installed and fluid displacement is complete. The dissolvable technology has an extensive track record in unconventional completions and proven in multiple installations with inflow control device (ICD) completions. The EquiFlow AICD washpipe-free completion maintains the capability to washdown, circulate from the end of the bottomhole assembly (BHA) to navigate through tight spots and allow fluid displacement, with the additional benefits of rig time savings and greater operation efficiency by reducing risk

Balances production flow and restricts unwanted production fluid, even with minimal viscosity difference between the produced fluids.

Helps delay and reduce the flow of unwanted fluid and stimulates balanced production throughout the entire interval.

Combines the benefits of inflow balancing with the flexibility to reconfigure the ICD as needed.

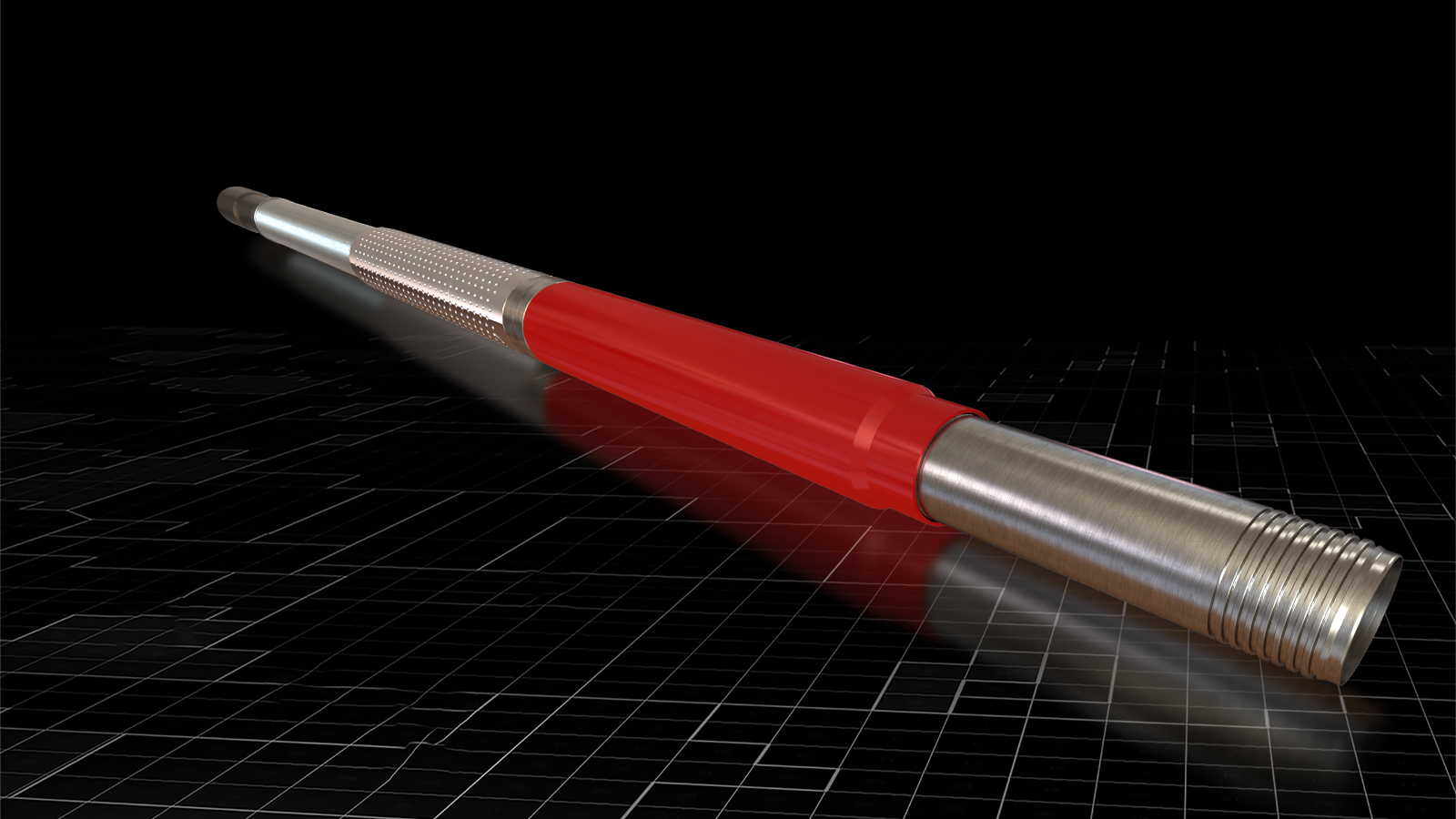

The EquiFlow ICD with sliding sleeve combined with the PetroGuard® sand screen provide inflow control technology with a mechanical sliding sleeve functionality.

Increasing oil recovery at lower cost with washpipe-free ICD completions.

Maximize production efficiency and improve steam-oil-ratio in SAGD wells.

ONEPETRO.org

EquiFlow® washpipe-free ICD completions help reduce operational time and costs, and upon dissolution of the dissolvable plugs, delay gas and water breakthrough.

Paper presented at the Offshore Technology Conference, Houston, Texas.

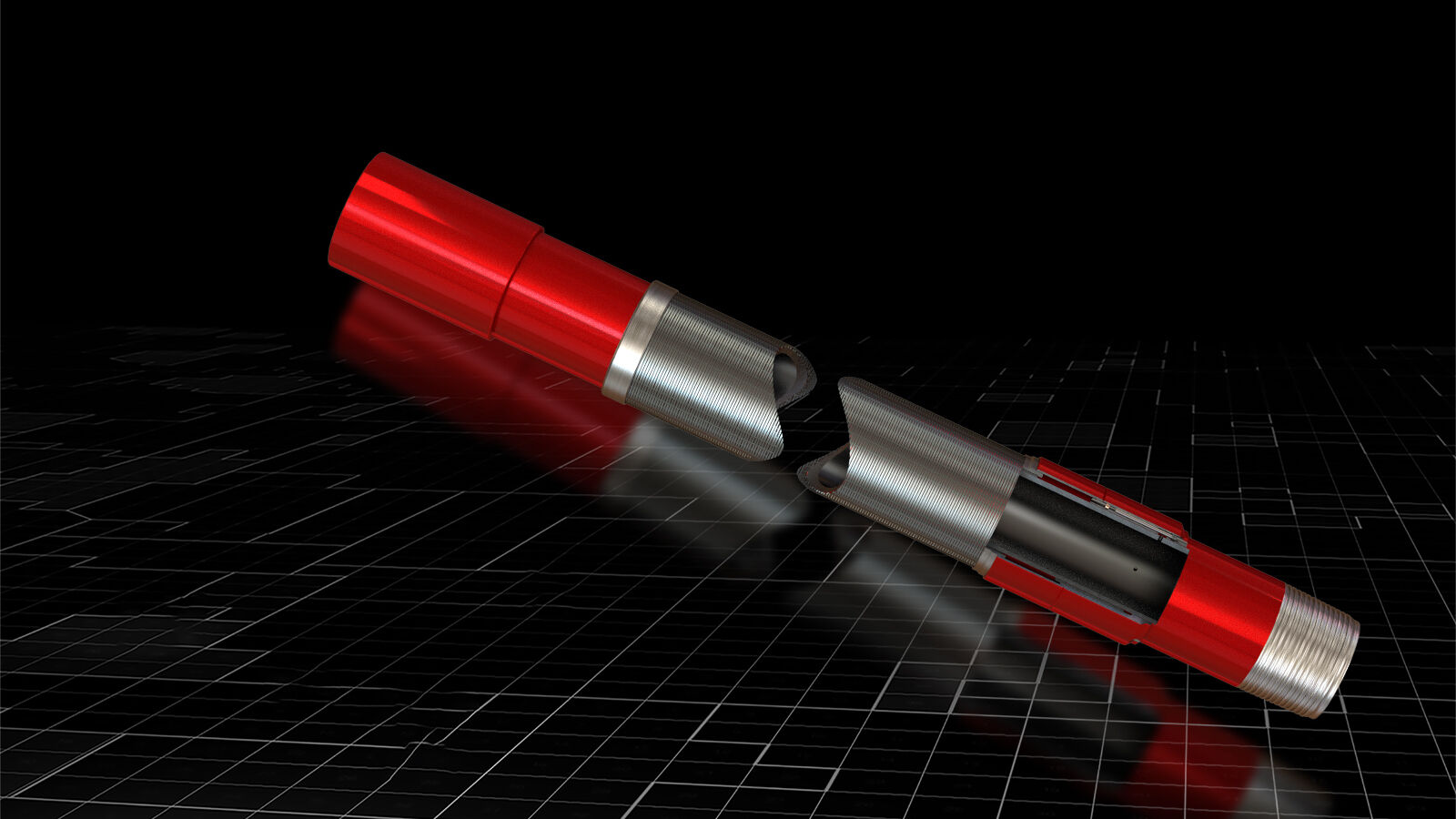

READ MOREThe EquiFlow ICD can be equipped with mechanical isolation plugs to temporally plug the ICD flow path, offering a washpipe-free installation method for ICD completions.

The mechanical control mechanism is incorporated into the ICD to temporarily isolate the flow paths and retain pressure while the lower completion is run in hole.

Applications

The EquiFlow Washpipe-Free module is suitable for all ICD applications.