Search

Search

Search

Search

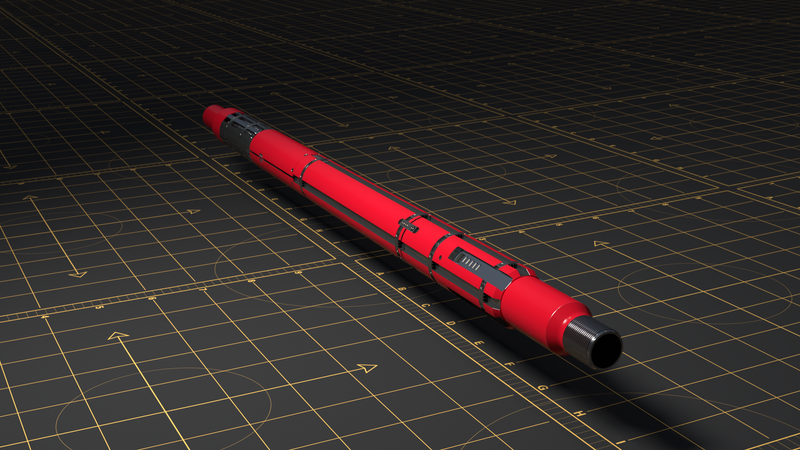

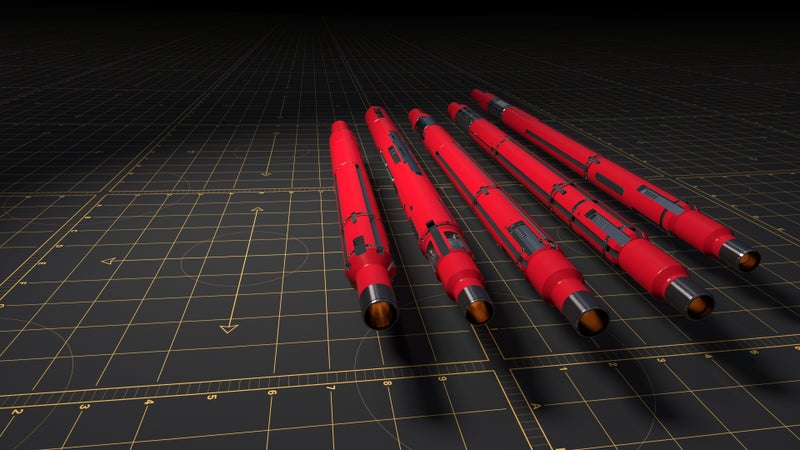

Next-generation electro-hydraulic control system delivers fast, precise, bidirectional choke control and manages up to 12 ICVs using only three control lines

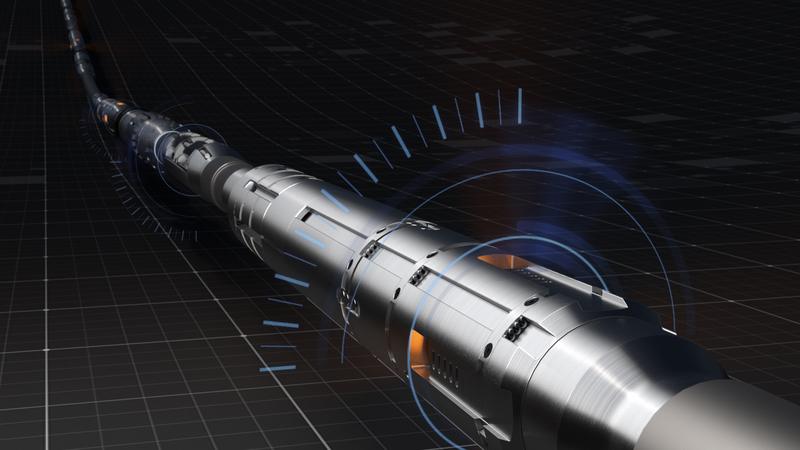

Talk to an expertThe Turing® electro-hydraulic control system is a multidrop tool. It provides fast, reliable, bidirectional zonal control of up to 12 ICVs using only three control lines—two hydraulic and one single-conductor electric line. The one single-conductor TEC can also be multi-dropped to the DataSphere® downhole gauges. Operators can remotely and selectively adjust flow rates and pressure across reservoir zones quickly and with precision. This system design enhances the efficiency and flexibility of downhole ICV management to optimize production and maintain peak performance throughout the lifecycle of a well.

Integrated with the Halliburton DataSphere® monitoring system and unified controller card (UCC), it enables real-time data collection and analysis to empower operators to make informed decisions. System commands are transmitted via a single-conductor TEC to simplify installation, reduce complexity and associated risk, and enhance reliability. This efficient system architecture leads to more reliable operations and helps provide significant cost savings in both OPEX and CAPEX, particularly in subsea applications.

The direct hydraulics downhole control system uses direct hydraulic control lines from the surface to remotely actuate downhole flow control devices.

The Accu-Pulse™ module enables incremental opening of a multi-position ICV to control produced or injected fluid rates for enhanced reservoir management.

The SmartPlex® II downhole control system is an electro-hydraulic multi-drop system that provides reliable zonal control of multiple valves in a single wellbore.

The debris-tolerant HS interval control valve (HS-ICV) enables deployment of Halliburton SmartWell® systems in high-pressure, deepwater environments.

Halliburton SmartWell® completion systems allow you to collect, transmit, and analyze completion, production, and reservoir data and control and monitor selected reservoir zones remotely and in real-time.

Halliburton intelligent flow control systems provide a method to integrate manual or automated surface control systems with downhole SmartWell® completion equipment.