Search

Search

Search

Search

Platform maximizes profitability by uniting systems, modernizing operations, and mitigating risks

Download PDFMitigate risks and maximize profitability

Fenris gas and condensate field

LOGIX® site manager, a platform designed for real-time valve monitoring and control, was chosen to:

Integrating legacy systems with the LOGIX® autonomous drilling platform advanced automation resulted in:

The Fenris gas and condensate field, operated by Aker BP in the North Sea, represents a complex environment for oil and gas operations. Drilling high-pressure/high-temperature (HP/HT) wells in the regulated North Sea location demanded precision, safety, and efficiency. Halliburton, Noble Drilling, and Aker BP (a strategic alliance established in 2017) applied their expertise in automation to tackle the project's operations. Advanced automation technologies were necessary to mitigate risks and maximize profitability. The integration of the LOGIX® autonomous drilling platform site manager – for real-time valve monitoring and control – enabled Aker BP to improve safety monitoring, facilitate procedural compliance, and boost operational efficiency. This approach not only addressed the project’s complexities but played a critical role in the advancement of automation in this complex drilling environment.

Outdated systems can lead to critical gaps in visibility and coordination. This can negatively affect safety and operational efficiency. Fragmented systems often include legacy sensors, manual workflows, and disconnected systems. This can can lead to siloed data and misaligned processes. Procedural gaps often refer to paper-based procedures that lack live feedback. This increases the risk of flow-path misalignments or incidents caused by poor valve tracking. Without real-time monitoring of valve positions or flow paths, operators are forced to rely on reactive measures. This effort can result in errors, financial losses, or regulatory penalties. The consequences of disconnection can cause operational downtime and cost operators millions annually in nonproductive time.

Safety incidents, such as valve misalignments, can escalate into environmental spills or equipment failures. Additionally, regulatory scrutiny has tightened and made procedural compliance more critical than ever.

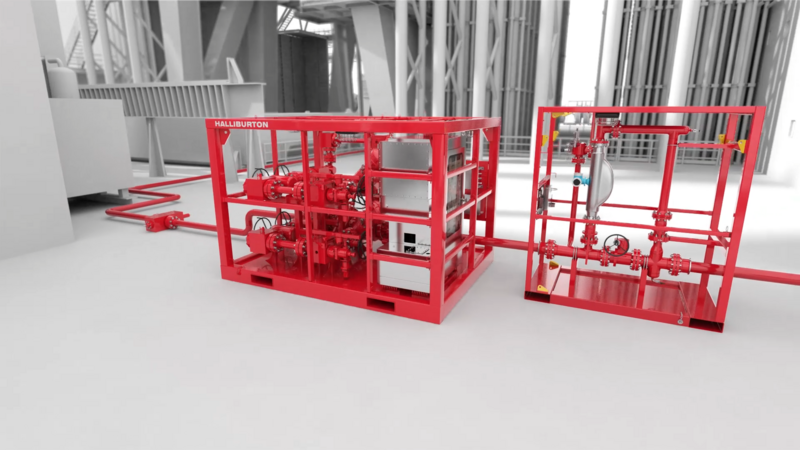

Faced with the demands of HP/HT wells and Norway’s stringent regulations, Aker BP turned to the LOGIX® autonomous drilling platform site manager within its alliance with Halliburton and Noble Drilling. This approach modernized operations and unified fragmented legacy systems with advanced internet of things (IoT) capabilities. This approach helped the operator improve how it manages safety risks and operational hurdles. LOGIX® autonomous drilling platform site manager successfully integrated 26 existing valve sensors, along with rig-wide pressure and flow data, into a unified platform. The approach provided seamless data aggregation from legacy systems and helped capture all critical signals without infrastructure upgrades.

Additionally, 96 wireless valve position sensors were installed across the Noble Integrator rig with a custom LoRaWAN network. These sensors provided real-time visibility into valve positions, and enabled operators to monitor critical components remotely and to reduce manual inspections in hazardous zones. An automated flow path detection system continuously monitored valve alignments, pump states, and flow configurations to automatically detect any critical issues. Any misalignment or deviation from safe configurations triggered immediate alerts.

Using browser-based technology and edge computing, the LOGIX® platform synchronized human–machine interface (HMI) systems across onsite teams and remote stakeholders – allowing operators to assign controller or viewer roles to ensure clarity and control while maintaining secure remote access via internet-connected devices.

Wireless valve sensors deployed

Legacy valve sensors integrated

The LOGIX® site manager platform enabled Aker BP to deploy 96 sensors across the jackup rig and to integrate 26 existing valve sensors, as well as pressure and flow data, into a unified platform. With these installments, flow paths could be automatically monitored across all critical configurations, and digitized workflows ensured procedural compliance with real-time feedback.

By utilizing the LOGIX® site manager platform, Aker BP was able to increase operational alignment, with all stakeholders having access to live system updates for better decision making. This, in turn, enhanced safety, since automated flow path detection reduced manual oversight requirements for unmanned operations while ensuring that critical safety parameters were met at all times. Additionally, digitized workflows eliminated reliance on paper procedures, thus reducing procedural gaps and improving accountability across teams. Bridging legacy systems with the LOGIX® site manager platform and IoT technology allowed the operator to modernize operations while avoiding costly infrastructure replacements.

Enabling technology that can accomplish efficiency goals while mitigating drilling risks.