Search

Search

Search

Search

LOGIX® autonomous drilling platform and iCruise® intelligent rotary steerable system set new benchmarks, saving 5 days of rig time in extreme conditions

Download PDFDeep Water

identify and map challenges for a better understanding to improve performance

INDONESIA

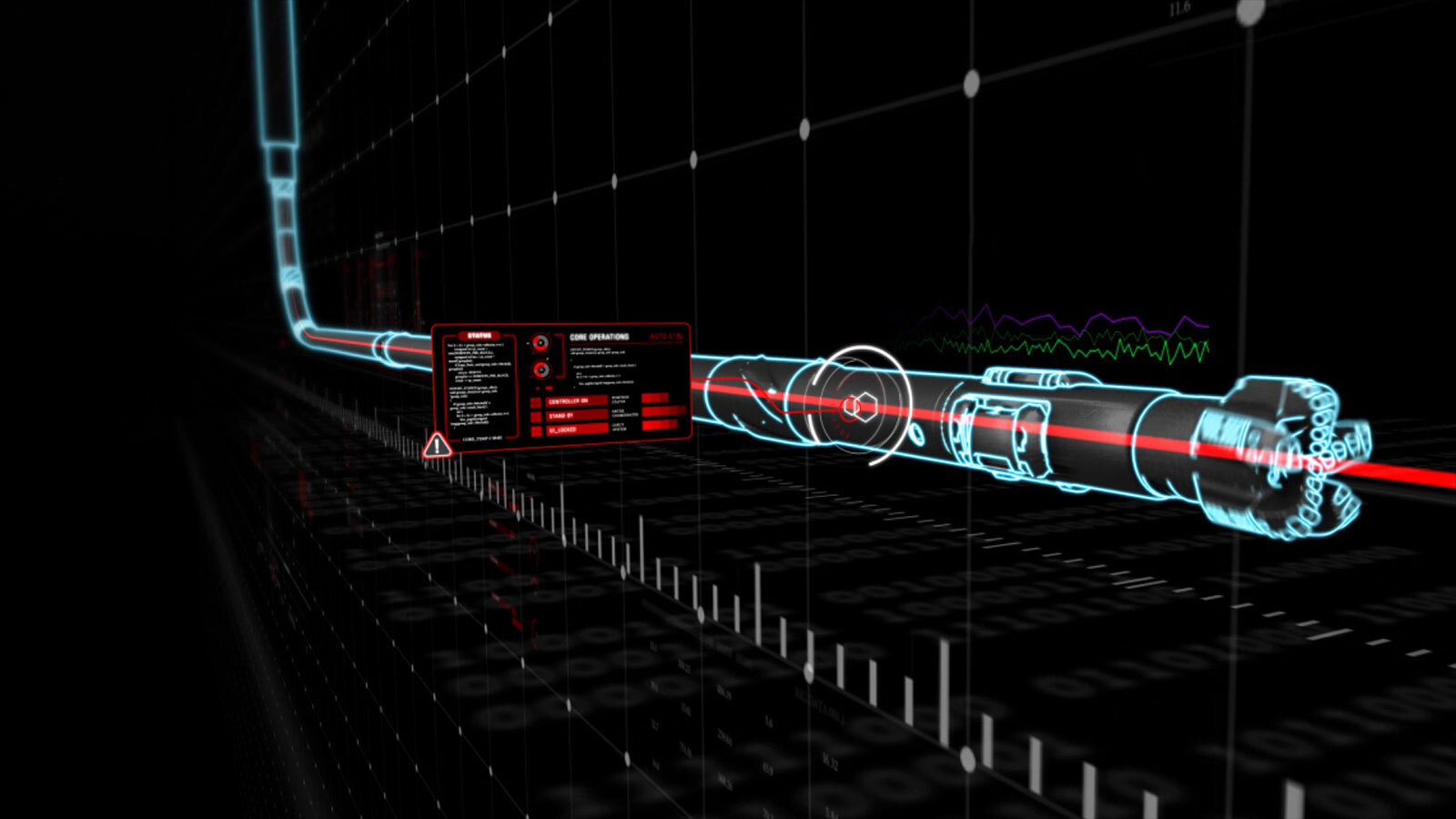

Logging-While-Drilling (LWD) solutions include:

The Sorik Marapi field, operated by KS ORKA, is one of the largest developing geothermal projects in Indonesia, located in North Sumatera. Approximately 39 exploration and development wells have already been drilled to depths of up to 2715 m MD, with eight of the wells having temperatures as high as 325°C.

These wells were executed with the assistance of traditional methods like measurement-while-drilling (MWD) and steerable motors. Currently, the standard technology in a geothermal environment is limited to basic telemetry derived from directional, PWD (Pressure While Drilling), temperature, and vibration sensors. In this type of challenging drilling environment, however, the telemetry commonly used is a high-speed electromagnetic (EM), bi-directional telemetry system, in which data are encoded as an electric potential (voltage) created between the drillstring and the formation.

As the Sorik Marapi field presents multiple drilling challenges, the operator recognized a need to identify and map those challenges against the different geothermal formations for a better understanding and to improve performance. The first step was to purchase a minimal logging-while-drilling (LWD) application for cost-effective operations in geothermal drilling with static temperatures in the field that are up to 325°C. But that was just the beginning.

Additional LWD services were provided by Halliburton to increase knowledge about the different challenges for each formation drilled in the fi eld. The plan was two-fold: First, target Well “XXE-05” to acquire this data while drilling and concurrently provide steam and hot water for Phase III/IV of a power plant being developed for the Sorik Marapi field; and second, to identify and test the extent of the northwestern sector of the high-temperature reservoir, located west of Pad 1.

The following tools were selected for gathering LWD data with strategic purposes in mind:

The ACAL is an ultrasonic acoustic caliper sensor, featuring three transceivers mounted at 120° intervals around the tool collar. A temperature measurement is also available from this sensor.

The PWD is a pressure-while-drilling sensor that comprises quartz transducers to measure the internal or bore pressure and the external or annular pressure. This data can be used to achieve realtime equivalent circulating and static density (ECD and ESD).

The DDSr™-HCIM sensor responds to changes in acceleration in the X, Y, and Z-axis directions that occur in response to impact between the bottomhole assembly (BHA) and the borehole wall. Accelerometers are the primary source of vibration data acquisition, while magnetometers and gyroscopes are used for rotational speed measurements, known as “stick-slip indicator” measurements.

The addition of caliper measurement capabilities and a high-resolution vibration sensor helped illuminate the unique challenges of each well drilled, allowing the operator to characterize the different types of vibration and borehole quality.

Figure 1 shows the caliper and drilling mechanics response for the XXE-05 well in a 12-1/4-in section, showing the interval divided into several study areas.

Figure 2 additionally shows highlighted washout measurements in the study area. Utilized for subsurface analysis, the plot shows average caliper, stand-off image, and borehole cross section measurements.

Figure 3 shows a vibration characterization generated by using all available data from the LWD sensors throughout the 12 1/4-in section with different torsional lateral vibrations that were predominant at different levels based on the formation being drilled and with some severe vibration events that were recorded in the high-frequency files for some of the formations drilled.

The PCDC (photonic crystal directional coupler) sensor consists of accelerometers and magnetometers for directional drilling purposes. It provides measurements of total gravity, magnetic field, and dip angle, which are used to calculate the directional survey data comprising inclination, azimuth, and toolface.

Directional Drilling

Smart design meets drilling automation

Learn More

Designed for fast drilling, accurate well placement, and reliable performance.

Automating well construction across plan/design/execution phases enables real-time decision-making to achieve predictable results.

Halliburton real-time operations enables performance improvements at almost every step of the drilling process