Search

Search

Search

Search

6-¾” iCruise® intelligent rotary steerable system and electromagnetic telemetry (EMT) system delivers high ROP

Download PDFUnconventionals

Use RSS and EMT system to drill at a high rate of penetration (ROP)

DJ Basin, Colorado

An operator wanted to drill an 8-½” mono-bore well while needing to address the drilling challenges of holding inclination in the intermediate section, drilling an 8° curve, and continue into the horizontal section. This needed to be accomplished while maintaining high rate of penetration (ROP) and utilizing a mono-bore design. Halliburton Sperry Drilling and Drill Bits Services team collaborated with the operator to provide an engineered drilling solution, and designed the bottom-hole assembly (BHA) specific to the needs of the wellbore. The design exceeded ROP KPIs of 850’/hr and reached as high as 1200’/hr in the intermediate section. It continued to deliver the required DLS to complete the curve and drill into the horizontal.

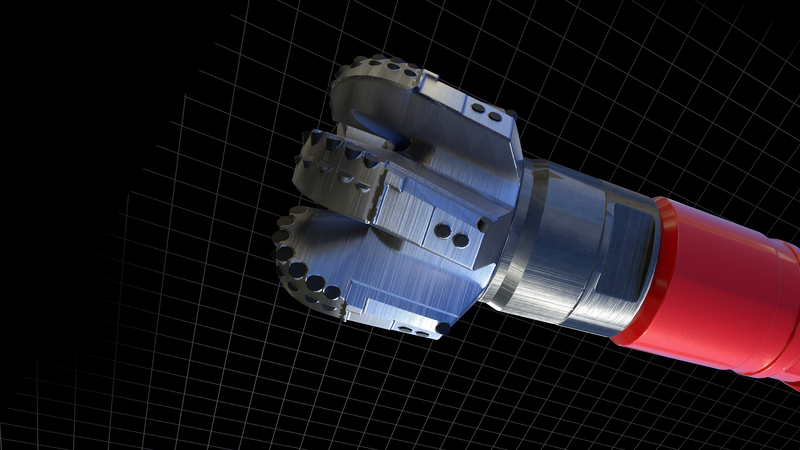

Implementing recent advancements in electromagnetic (EM) technology, coupled with the iCruise® intelligent rotary steerable system (RSS), allowed two way communication and downlinking while drilling at high rate of penetration above 1000’/hr. This technology also provided surveys while making connections which aided in reducing overall downhole hours. The motor assisted RSS by the NitroForce™ high-torque, high-flow motor paired with the GeoTech GTi55MBO drill bit design. This solution reduced well time by beating the expected KPI of the tangent section, reaching the production liner casing point, for a total of 19,830’ drilled at a final depth of 21,431’ MD. Reduced tortuosity and friction allowed installation of the production casing with no issues, helping the operator maximize asset value.

Feet Drilled

average rate of penetration (ROP) per hour in feet

Feet Measured Depth (MD)

Halliburton delivers drilling performance to increase asset recovery, improve wellbore quality, and reduce overall well construction costs.

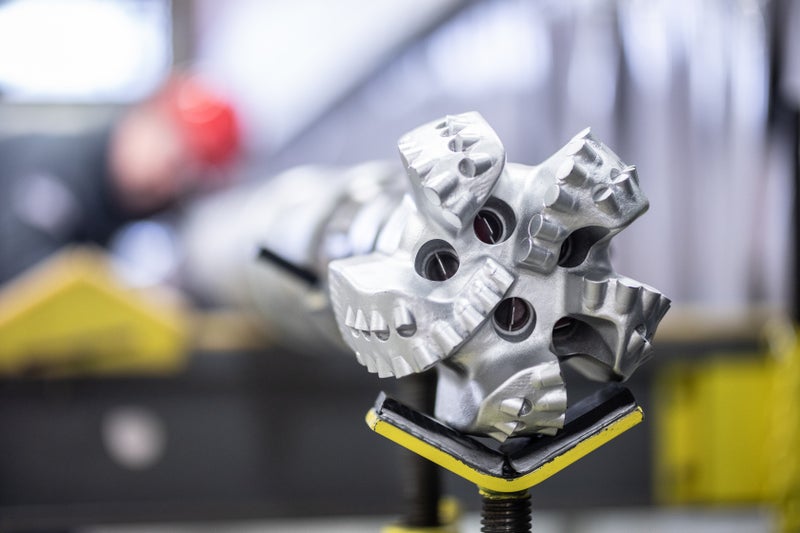

Fixed cutter and roller cone bits are engineered to optimize performance by using our global network of engineers to design the right bit for the right application.

Reduce well time through fast drilling, fast tripping time and quicker casing drill outs.

Provides the power and performance to consistently deliver faster and longer runs.

GeoTech® matrix and steel body drill bits are customized to deliver performance across all drilling applications.

Telemetry services transmit downhole data from MWD/LWD tools to the surface to provide operators real-time drilling and reservoir insights.