Search

Search

Search

Search

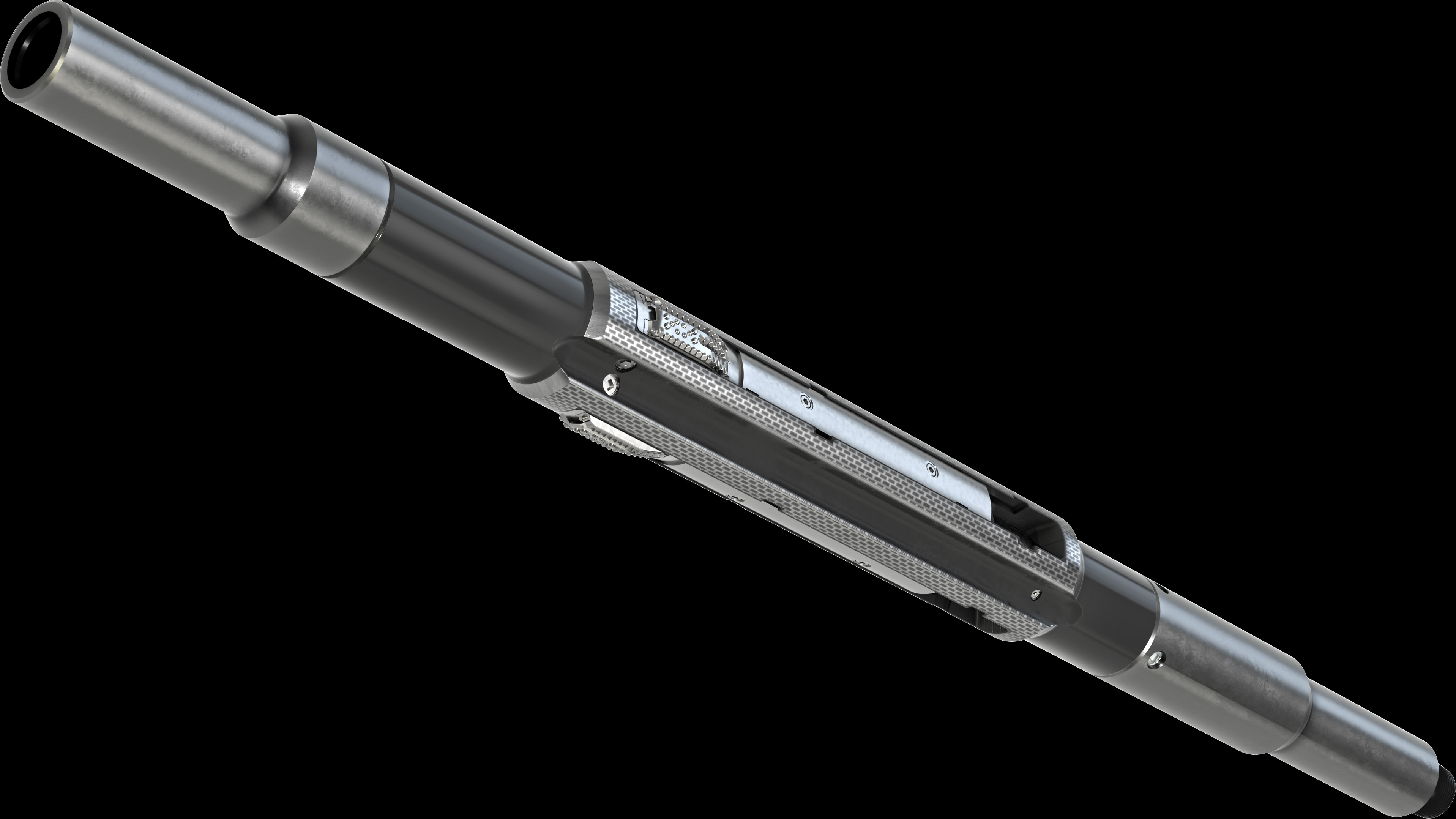

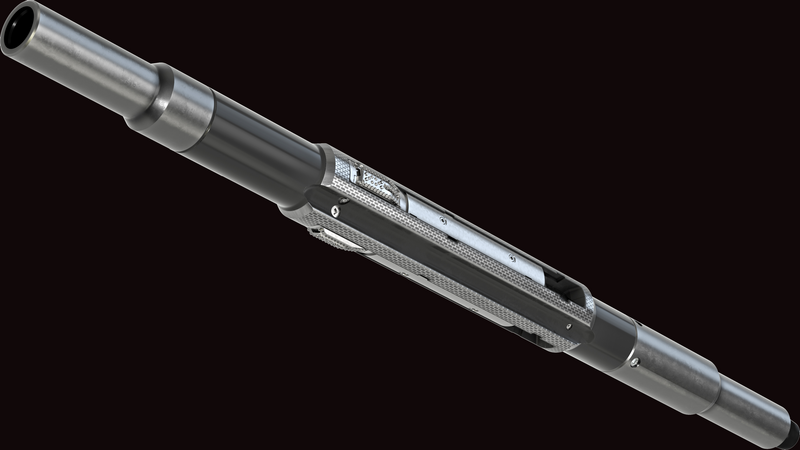

XR PrimeTM 1200 reamer hole enlargement tool provides durability and performance in coal sections

Download PDFDifficulties with pulling out of hole and running casing due to coal sections

Offshore Malaysia

An operator faced significant challenges in an offshore Malaysian asset, such as pulling out of the hole (POOH) and running casing. The issues encountered in the offset well, drilled two weeks prior, highlighted the need for an effective solution to facilitate smooth operations in the new well.

During the drilling of the well, the customer experienced difficulties POOH after they reached total depth (TD) of the 12 ¼-in. hole section due to various coal sections. In addition, there were challenges in running the 9 5/8-in. casing into the 12 ¼-in. hole section. These issues caused delays and increased operational costs.

To address these challenges, the customer used the XR PrimeTM 1200 13 ½-in. reamer hole enlargement tool combined with a polycrystalline diamond compact bit. The solution involved a single run (reaming while drilling) to open the 12 ¼-in. pilot hole to a 13 ½-in. hole. The Prime arm was recommended for increased durability in the build section. The section ranged from 65° to 82° inclination over a long interval of 1,983 m.

The underreaming operation in the well was completed in a single run. Key outcomes included:

The operation saved rig time and helped the operator achieve their objectives. The successful enlargement of the hole and smooth casing run highlighted the effectiveness of the chosen solution.

The XR Prime™ reamer hole enlargement tool provides extreme durability and stability in the most challenging applications.

Halliburton’s TDReam™ hole enlargement tool reduces the rathole length to less than 3 feet in a single run, saving time and money.