Search

Search

Search

Search

Maximize efficiency and reduce fuel costs with high-performance electric fracturing.

A combination of factors has driven the increase in adoption of electric fracturing. First, the industry has committed to lower emissions through cleaner, more efficient frac operations. By eliminating diesel, operators achieve significant cost savings. Finally, the industry’s constant focus on efficiency further fuels demand for electric fracturing.

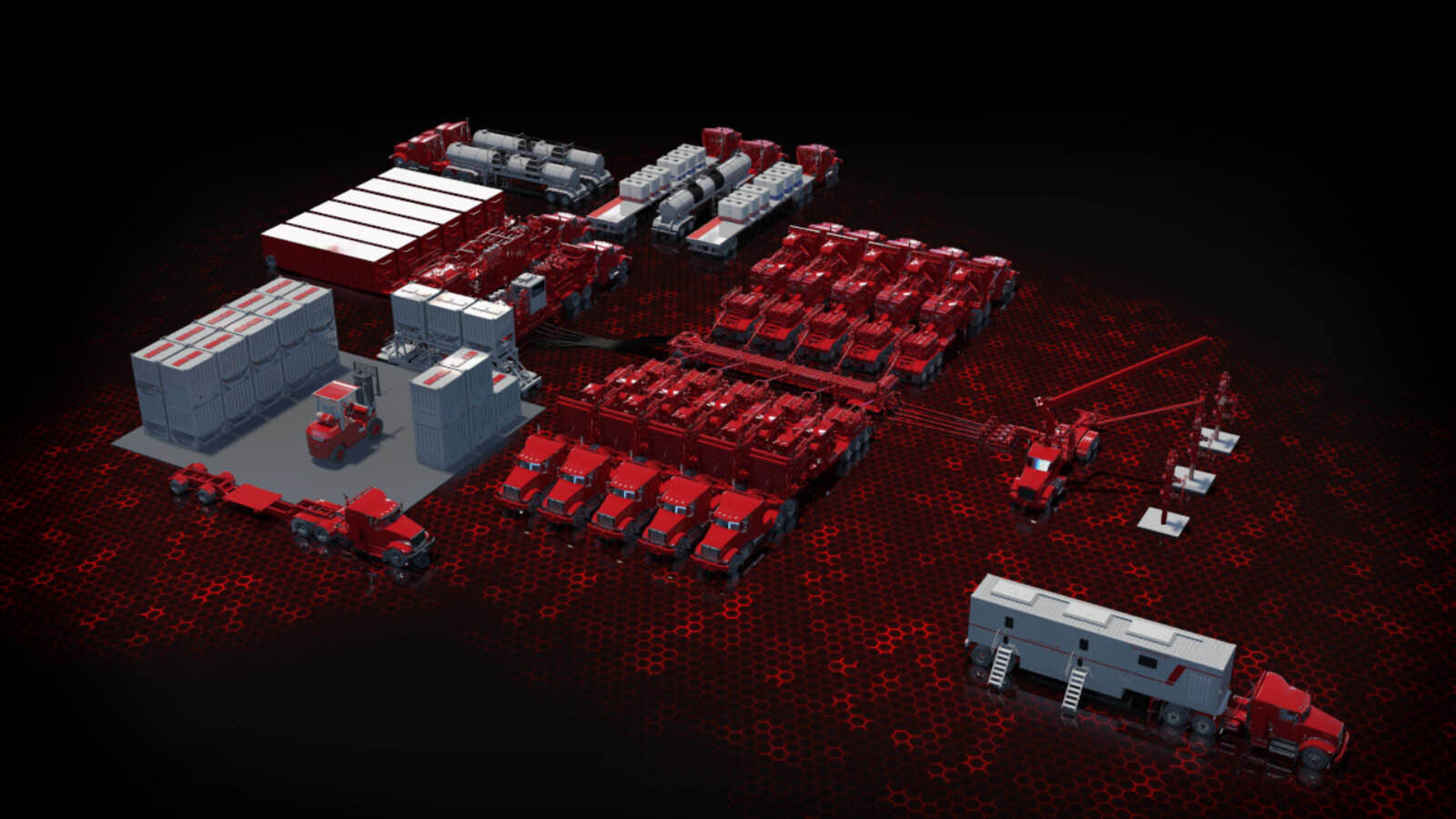

The ZEUSTM electric fracturing system delivers differentiated value on each of these drivers. It offers an integrated, all-electric frac site that lowers emissions, reduces fuel costs, and maximizes efficiency gains for our customers.

In Diesel Cost Saved per Month on Simul-frac Operations

Faster Stage to Stage Transitions

More HHP Hours Pumped per Month

Lower Emissions Using Reciprocating Engines

The ZEUS system was built for high service intensity frac operations, with the ability to pump higher volumes, rates and pressures, right out of the box. The systems’ proven track record includes pumping more than 500 hrs in the first 30 days of operations for multiple operators across North America.

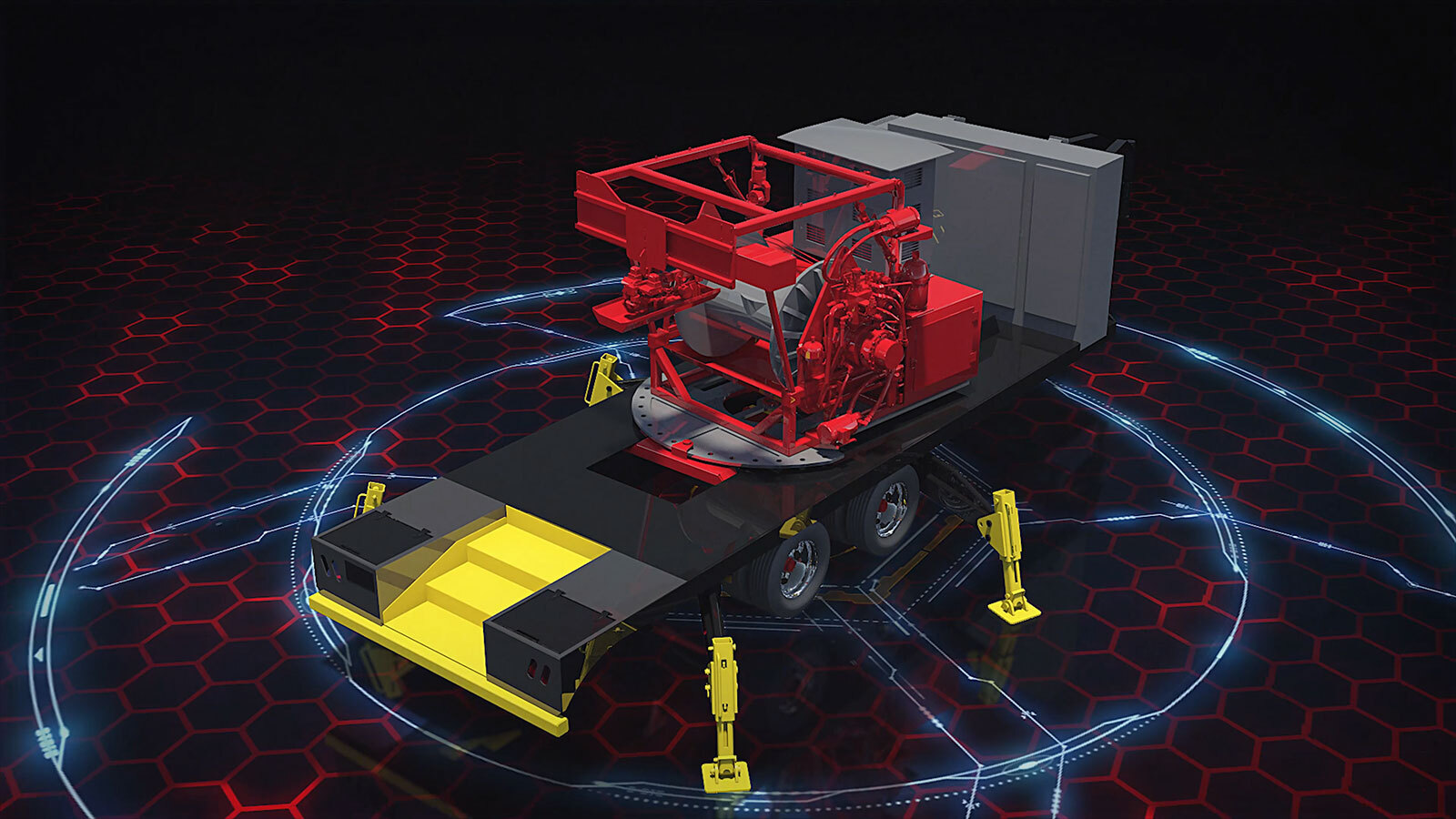

Every ZEUS pumping unit can achieve up to 5,000 HHP consistently, allowing operators to pump higher rates, using half the equipment necessary. With the reliability and efficiency of its electric power train, it helps operators reduce dollars spent per completed lateral foot. The electric power train provides faster rate response and more precise control. An electric system also eliminates non-productive time associated with diesel engines, transmissions and hydraulics.

The result is an electric fracturing system that has delivered an average of 30% faster transition times and 11% more HHP hours pumped per month—this means more pumping hours, more lateral feet completed, and more cost savings for operators.

In terms of lower emissions, the system offers flexibility and compatibility across multiple sources, including reciprocating engines, micro grids and grid power. Each of these power solutions results in lower emissions, compared to diesel and dual-fuel operations.

When powered by the grid, the ZEUS system can reduce overall emissions up to an estimated 45%, compared to Tier 2 diesel engines1. When grid power is unavailable, reciprocating engines provide operators with mobile power generation proven to deliver reliability, consume less fuel, and create fewer emissions, compared to other mobile power sources. While using reciprocation engines, the system reduces overall emissions by up to an estimated 30%, compared to Tier 2 diesel engines1. The power density provided by reciprocating engines also allows operators to scale power supply to meet their specific job design, eliminating the need to pay for unused, stranded power.

In addition to lower emissions, electric fracturing significantly reduces fuel costs. During a simul-frac operation, the system can displace more than 900,000 gal of diesel per month or 11 million gal annually2.

The Halliburton ZEUS electric fracturing pumping unit delivers higher pump rates with 5,000 hydraulic horsepower.

Explore

An electric manifold with fewer failure points, faster rig-up and higher rate capacity.

Explore

An integrated system for hydration, additive, and slurry blending.

Explore

All-electric system that can be remotely operated for safety and efficiency

ExploreWorld Oil Article

In the evolving landscape of hydraulic fracturing, a transformative synergy of electrification, automation and real-time optimization has emerged. The commingling of these technologies is paving the way for unprecedented efficiency and performance gains, while also reducing costs and NPT.

Read MorePodcast

Daniel Energy Partners sits down with Chesapeake Energy to talk about a recent trip to the Marcellus to visit Halliburton’s electric frac fleet. Listen in as they share key benefits of the electric fleet and stats from their first pad in PA.

Listen Now